Basics of Weaving and Woven Fabrics

Weaving Process, Weaving Patterns, Structures, and Properties

Weaving is the process of making cloth with two components, a warp, and a weft, and can be done by very simple techniques on a complicated loom.

Preparing the Warp Yarns for Weaving

Before their use on the loom, warp and filling yarns must be prepared for weaving. In preparation for weaving, each warp end (yarn) must be threaded through its own drop wire, heddle eye, and reed dent. The Drop wire is a device that will stop the loom if an end should break, the heddle eye is the opening in a heddle that carries the yarn, and the reed comb-like device that will push each filling yarn close against the completed fabric.

Placing the warp yarns on the loom is done either by drawing-in or by tying-in. Heddle wires are held in frames called harnesses. The number of harnesses required for the loom is determined by the weave.

Preparing the Filling Yarns for Weaving

Yarn that is to be used for filling must be packaged in some form that allows it to be unwound easily for transport through the shed is called a shuttle and is made up of a wooden carrier into which a quill or pirn is placed.

Basic Weaving Operation – 4 basic steps

Primary Motions

Once the filling yarns have been prepared and the warp beam containing the sized yarns is placed at the back of the loom. The warp yarns are conveyed to a cylinder called the cloth beam which is in front.

The loom goes through a series of motions

- Shedding: raising and lowering of warp yarns by means of the harness to form shed, opening between warp yarns through which weft yarn passes

- Picking: inserting of weft yarn by the shuttle through the shed

- Beating up: packing the weft yarn into the cloth to make it compact

- Taking up: winding newly formed cloth onto the cloth beam, Letting off: releasing yarn from a warp beam

Weaving Patterns Decoded

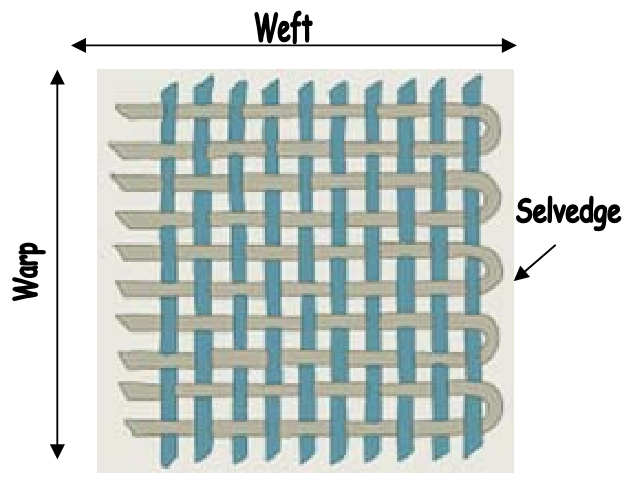

- Weft: The horizontal yarns are called weft yarns.

- Warp: Warp yarns run vertically the length of the fabric, known as the grain.

- Selvedge: The weft yarns are wrapped around the warp yarns to create an edge to the fabric, known as the Selvedge.

- Bias: the diagonal or cross grain of a woven fabric.

- Grain: runs the length of the fabric.

Classification of Woven Fabrics

- Basic/Simple Weaves

- Compound/Complex/Novelty Weaves

Basic/Simple Weaves: 3 basic weaves

A basic weave, that is a simple alternate interlacing of warp and filling yarns. Any type of yarn made from any type of fiber can be manufactured into a plain weave fabric.

A basic weave that has a diagonal effect on the face, or right side, of the fabric. In some twill weave fabrics, the diagonal effect may also be seen clearly on the back side of the fabric.

A basic weave, characterized by long floats of yarn on the face of the fabric. Satin weave fabric always has the warp yarns floating over filling yarns.

Compound/Complex/Novelty Weaves

- Dobby Weave

- Jacquard Weave

- Double Cloth & Double Weave

- Pique

- Pile Fabrics

- Surface Figure Weaves

Woven Fabrics Characteristics

- Oldest & widely used method of construction

- Made with two or more sets of yarns interlaced at right angles to each other. Yarns in lengthwise direction: warp/ends, yarns in crosswise direction: filling/weft/picks

- Selvage: self-edge of fabric on both sides along the length of the fabric. Made with more closely placed warp yarns, width:1/4th inch. The selvage prevents the fabric from raveling. It usually made more compact and stronger than the rest of the fabric. Plain, split, fringe, fused, leno & tucked selvage.

- Grain: indicates warp & weft positions in the fabric.

- Lengthwise Grain

- Crosswise Grain

- Bias & True Bias

- Identification of grain: selvage parallel to lengthwise grain, less stretch along warp yarns, warp yarns lie straighter & stronger, more twist in warp yarns, the single yarn is used.

- Fabric lengths & widths: length – 40 – 100 yards or more, width – 20 – 60 inches (handwoven:27 – 36 inches, Power loom: 40 – 60 inches)

- Done on a machine called handloom or power loom

Structural Properties of Woven Fabrics

-

- Warp and weft densities

- Warp and weft yarn counts

- Weave

- Crimp

- Weight

- Thickness

- Cover

- Fabric width and piece length

The appearance of Woven Fabrics

- Surface characteristics (luster, opaque)

- Texture (i.e. the visual & tactile perceptions for velvets, silk fabrics)

- Ornamentation:

- Using of colored yarn: When colored yarns are used in one direction, color stripes are produced along the length or across the width of the fabric. When colored yarns are used in warp and weft direction together, a check effect produced. These arrangements are commonly used in fabrics with plain weave or 2/2 twill.

- Changing the yarn count: Stripes and check effects can be produced by using different yarn counts in one or both directions. For instance, rib effects can be produced by using different yarn counts in plain weave fabrics.

- Changing the yarn twist: Using combinations of different twist levels and twist directions along the length of the fabric or across the width (or both), different effects can be produced in the fabric. Also, different amounts of twist produce different shrinkage (contraction) characteristics in different parts of the fabrics and so change the appearance.

- Combining different weaves: There are many ways to combine different weaves. Stripe, check effects and figured fabrics can be produced.

- Different finishing techniques: Treatments such as dyeing, printing, mercerizing or coating can change the surface characteristics of the fabrics.

- and combinations of any of the above.

Mechanical Properties of Woven Fabrics

- Tensile strength: It implies the behavior of the fabric under different loads applied.

- Extensibility: It is the ability of the fabric to extend under load.

- Tear Strength: A hole has been made in the fabric because it has been pulled sharply.

- Abrasion Resistance: Resistance of the fabric against the surface friction.

- Crease Resistance: Creases are irregular lines that appear on cloth when it has been crushed.

- Pilling Resistance: Hairs on the surface of a fabric tend to collect into little balls (pills) and if the fibers are strong, these balls do not break off – this spoils the appearance of the fabric.

Chemical Properties of Woven Fabrics – correlated to fiber properties

- Composition of fiber

- Chemical stability

- The effect of heat, moisture, acids, alkalis, solvents and other chemicals on fibers

- The affinity of the fiber for dyestuffs

- Moisture holding ability

- Burning behavior

Common terms used by the weaving industry

- GRAIN: Position of warp yarns relative to filling yarns in the fabric.

- On-grain: Warp yarns lie parallel to each other (lengthwise) & weft yarns lie parallel to each other (crosswise). Warp & weft yarns lie perpendicular to each other.

- Off-grain: Lowers fabric quality, the fabric does not drape properly, Printed designs are not straight.

- Skewed fabric: Filling yarn is at an angle other than 900 to warp yarns.

- Bowed fabric: Filling yarns dip in the center of the fabric.

- FABRIC COUNT/THREAD COUNT: No. of warp & weft yarns per square inch. Denotes closeness or compactness of fabric. Higher the count, better the quality of fabric, higher strength. E.g. 80 X 76 (80 warp yarns & 76 weft yarns in 1 inch). Fabric weight is measured in Grams per square meter (gsm).

- BALANCE: Ratio of warp yarns to filling yarns in a fabric.

- BALANCED FABRIC: Will have a ratio of warp to weft yarns as 1:1. E.g. Fabric count

of a balanced fabric: 78 X 78 or 64 X 60. This fabric is more durable. - UNBALANCED FABRIC: Will have a ratio of warp to weft yarns as 2:1. E.g. Fabric count of an unbalanced fabric: 144 X 76 or 100 X 60. It exhibits rib-like structure. Weaves are represented on graph paper or point paper. Each square of the paper represents the yarn that appears on the top.

Very good post.

https://advancetextile86.blogspot .com/2022/01/sustainable-clothing-sustainable-clothing-brands.htmlhi

why does the woven fabric changes appearance after wash and being dry .

A stripped woven r/p/n/s looked like a seersucker after dried

Can anyone help