Ring Spinning, the widely used yarn formation technique

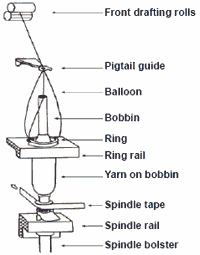

The Ring Spinning is the most widely used form of the spinning machine due to significant advantages in comparison with the new spinning processes. The ring spinning machine is used in the textile industry to simultaneously twist staple fibers into yarn and then wind it onto bobbins for storage. The yarn loop rotating rapidly about a fixed axis generates a surface referred to as “balloon”. Ring frame settings are chosen to reduce yarn hairiness and the risk of glazing or melting the fiber.

What is Ring Spinning?

Ring Spinning is the oldest of the present day spinning processes. The fibre material is supplied to the ring-spinning machine in the form of roving. The fibre mass of the roving is reduced by a drafting unit. The twist inserted moves backwards and reaches the fibres leaving the drafting unit.

Ring Spinning is the oldest of the present day spinning processes. The fibre material is supplied to the ring-spinning machine in the form of roving. The fibre mass of the roving is reduced by a drafting unit. The twist inserted moves backwards and reaches the fibres leaving the drafting unit.

The fibres lay around one another in concentric helical paths. The normal forces encountered by the fibres enhance the adhesive forces between the fibres and prevent fibres from flying or slipping past each other under the tensile strain.

It is the process of further drawing out roving to the final yarn count needed, inserting twist to the fibres by means of a rotating spindle and winding the yarn on a bobbin. These three stages take place simultaneously and continuously.

A mechanically driven spindle, on which the yarn package firmly sits, is responsible for a twist. A stationary ring is around the spindle, which holds the traveller. Yarn from the drafting unit is drawn under the traveller and then led to the yarn package. In order to wind the twisted yarn on a bobbin tube carried by the spindle, the traveller is required to cooperate with the spindle.

The traveller moves on the ring without any physical drive but is carried along by the yarn it is threaded with. The rotation rate of traveller is lower than the spindle, and this difference in the speeds of traveller and the spindle enables the winding of the yarn on the tube.

A controlled up and down movement of the ring determines the shape of the yarn package, called Cop or Bobbin. Ring spinning technology provides the widest range in terms of the yarn counts it can produce.

Ring spinning is a comparatively expensive process because of its slower production speeds and the additional processes (roving and winding) required for producing ring spun yarns. Ringspun yarns produce high quality and are mainly produced in the fine (60 Ne, 10 tex) to medium count (30 Ne, 20 tex) range, with a small amount produced in the coarse count (10 Ne, 60 tex) range. End uses include high-quality underwear, shirting, towels. The fibres in the ring yarn are highly parallel and helical in nature, and the fibre arrangement is uniform along the thickness of the yarn. The yarn has a compact structure, with essentially no wrapper or hooked fibres. The self-locked structure is the result of intensive fibre migration, which in turn is influenced by the triangular geometry of the spinning zone and the high spinning tensions. The high axial strength of the yarn is the result of a unique self-locked structure.

Basic Principles of Ring Spinning

Some of the basic principles of Ring Spinning are as follows:-

- Drafting Mechanism

To attenuate roving until the desired fineness is reached. - Consolidation(strength) Mechanism

To impart strength to the fibre by twisting it. - Winding and Package forming Mechanism

To wind up the resulting yarn in a package suitable for storage, transportation, and further processing.

How Ring Spinning affects the quality of the yarn?

Ring spinning is the first stage of post spinning in which yarn produced from the roving installed on the hanger on the ring machine. Ring process is the heart of the textile plant and there is a lot of factors which has an effect on the yarn quality.

- The speed of machine makes a major role on the yarn quality, as the speed increase of the ring machine, the imperfection (Neps 200%, Thick +50, Thin -50) of yarn increase.

- Hairiness is also affected by ring production process and mainly produced by the movement of burnt traveller and high speed of the machine.

- CV of the count is also very important and the ring spinning process is the last stage of the process where we can reduce the CV of yarn count.

- The imperfection of yarn count from a quality point of view is so important that every customer required this quality standard, that imperfection should be as minimum as possible.

- Ring spinning process also effects on twist variation during manufacturing of yarn. It causes major problems during working in the next process

Objectives of Ring Spinning

Following are the core objectives of ring spinning :

-

- To draft the roving fed to the ring spinning frame i,e to convert roving into very fine strand called yarn.

- To impart strength to the yarn by inserting the necessary amount of twist.

- To collect twisted strand called yarn onto handy and transportable package by winding the twisted thread on a cylindrical bobbin or tube.

Ring-frame

The ring spinning frame, commonly called the ring, is the conventional spinning system and it transforms the roving from the roving frame into spun yarn using the operations of:

- Drawing

- Twisting

- Winding

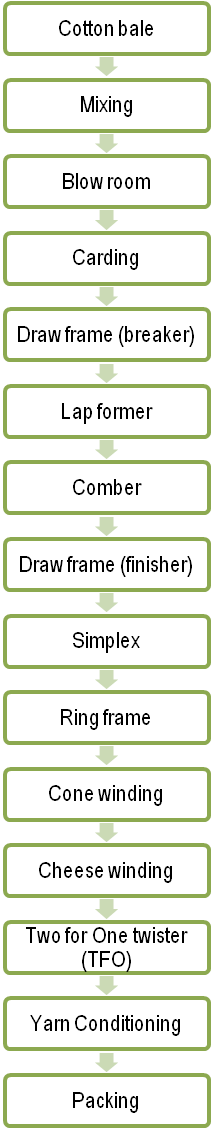

In the last step of yarn production, the staple fibres are fed to the ring spinning frame, after passing through the blow room (opening and cleaning) and the carding frame, drawing frame and flyer (separation of individual fibres, parallelization, the formation of a fibre tape). Here, the finished yarn is produced by drawing and rotating operations.

Some of the Operation involved in the ring frame

- Creel in

- Drafting

- Twisting

- Laying out

- Building

- Doffing

- Winding

Good information about process

Thank you it was very helping

Enjoyed reading through this, very good stuff, thankyou .

Probabely your thesis finished already, but anyhow actually if you are an Indonesian,..you can go to the Intitute of Textile Tecnology in Indonesia. it is in Bandu g city West Java. You can find a thousands refference for it.

Can you please recommend me some of book titles about textile? I recently am doing research about yarn making process for my thesis. Thank you.