Weaving – warp let-off and fabric take-up motions

Warp let-off system has a frequency converter, which is intended for letting off from warp beam or feeding unit. The drive is mounted either on the weaving machine or on a frame positioned behind the weaving machine. The let-off starts with a machine running signal; the speed of the let-off motor is controlled by a proximity switch mounted on the whip roller system and an internal speed memory. An alarm signal switches the weaving machine off in case of over tightened warp or any other error.

The warp let-off and fabric take-up motions are integral to the weaving process, ensuring the controlled release of warp yarns and the even winding of woven fabric. These motions play a crucial role in maintaining tension, alignment, and speed, ultimately contributing to the production of high-quality textiles. Weaving machines are designed with precision and engineering to achieve the necessary coordination between these motions, resulting in efficient and reliable textile production.

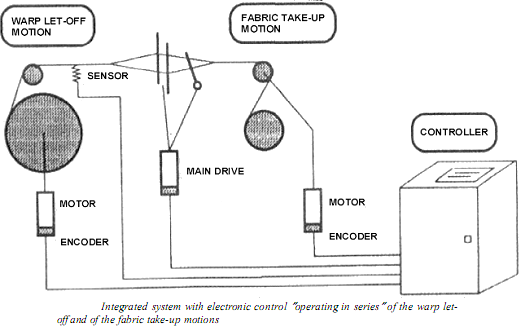

By now all modern weaving machines use integrated electronic systems which are operated by the drive and control unit of the machine. The warp beam and the take-up motions are driven by high precision servomotors equipped with a speed reducer, connected with the machine’s PLC through an encoder (a kind of electronic goniometer) and controlled through a closed adjustment ring. This ensures the synchronization of the weaving machine with the let-off and take-up motions (operating in series): practically the controller can know at any moment the exact position of the various devices.

A position sensor or a load cell signals at any moment the tension operating on the back rest roller and permits to adjust the let-off speed so that the tension remains absolutely constant from the start to the end of the weaving cycle. Furthermore, the positions of the take-up and let-off motions during the critical starting phases can be adjusted to the running behavior of the material in progress, in order to avoid stripes on the fabric. Also, the weft density can be varied without limitations during weaving and it is also possible to modify the warp tension by means of a simple keying in.

In weaving, the warp let-off and fabric take-up motions are essential components of a weaving machine that control the movement of the warp and fabric during the weaving process. These motions ensure the proper tension and synchronization of the warp and weft threads, resulting in the production of high-quality woven textiles. Let’s explore these two critical motions in detail:

Warp Let-Off Motion

The warp let-off motion is responsible for releasing the warp yarns from the warp beam and feeding them to the weaving machine at a controlled and consistent rate. This motion plays a crucial role in maintaining the tension, alignment, and speed of the warp yarns during the weaving process. Here’s how it works:

Components of the Warp Let-Off Motion:

- Warp Beam: The warp beam is a cylindrical or barrel-like structure that holds the warp yarn wound onto it. It is mounted on the weaving machine and rotates as the warp yarn is released.

- Brake Mechanism: The warp beam is equipped with a brake mechanism that controls the tension on the warp yarn. Proper tension is essential to prevent slack or excessive tightness in the warp.

- Let-Off Rollers: Let-off rollers are positioned between the warp beam and the weaving machine. They guide the warp yarn as it is unwound from the warp beam and maintain consistent tension.

- Tensioning Device: The tensioning device, often adjustable, ensures that the warp yarn is pulled off the warp beam at the desired tension. It can be controlled manually or automatically.

Batik designs – How to make Batik designs

What is Batik? How to manufacture Batik designs? Origin and details.

Function of the Warp Let-Off Motion:

The primary functions of the warp let-off motion are as follows:

- Tension Control: It maintains uniform tension on the warp yarn as it is fed to the weaving machine. Proper tension prevents breakage and ensures consistent weaving.

- Warp Alignment: The motion ensures that the warp yarns remain parallel and properly aligned during weaving, preventing twisting or misalignment.

- Speed Control: The let-off motion controls the speed at which the warp yarn is released, synchronizing it with the movement of the fabric take-up system to maintain the desired fabric density and weave pattern.

Fabric Take-Up Motion

The fabric take-up motion, as the name suggests, is responsible for winding the woven fabric onto the fabric beam or cloth roller as it is produced. This motion controls the speed at which the fabric is taken up and ensures that it is wound evenly and with the appropriate tension. Here’s how it works:

Components of the Fabric Take-Up Motion:

- Cloth Roller or Fabric Beam: The cloth roller or fabric beam is a cylindrical roller onto which the woven fabric is wound as it is produced.

- Take-Up Rollers: Take-up rollers are positioned between the weaving machine and the cloth roller. They guide the fabric and control its winding onto the cloth roller.

- Tensioning Device: Similar to the warp let-off motion, a tensioning device in the fabric take-up motion ensures that the fabric is wound with the appropriate tension.

Function of the Fabric Take-Up Motion:

The primary functions of the fabric take-up motion are as follows:

- Winding Fabric: It winds the woven fabric onto the cloth roller, preventing fabric from piling up on the weaving machine and ensuring continuous production.

- Tension Control: The motion maintains proper tension on the fabric to prevent stretching, wrinkling, or slackness in the woven material.

- Speed Control: The fabric take-up motion synchronizes with the warp let-off motion and the weaving process to ensure that the fabric is wound at the desired rate, corresponding to the loom’s weaving speed.