Terry towels – fabrics that can absorb large amounts of water

Design, manufacturing, and technological features of terry towels

A terry towel is a textile product which is made with pile loops on one or both sides covering the entire ground surface or forming pile strips, pile checks, or other pile patterns (with hemming end or with firm selvedges).

The manufacturing process of Terry Towels

Spinning

This is the process where selected fibres are converted to yarns of desired counts needed for towels. Some integrated textile towelling mills produce their own yarns for towels. They purchase bales of cotton of a specific grade as per their working plan.

- Mixing of fibres are formulated as per the required plan and are subjected to required atmospheric conditions before they are passed through the blow room line. Here strictly mill mixing plan is being followed. According to the mix plan selection of machines to process and their machine settings are made before mixing is allowed to pass through blow room line.

- Once planned results in the blow room process are accomplished then these fibres are passed directly through chute feeding to well-set carding machines and fibres are converted into slivers.

- These carding slivers are tested for various technological parameters before they are passed to next process Drawing frames. These draw frames are set as per working plan and slivers are passed through for effective blending and parallelization of fibres. Draw frame slivers are tested for parameters and if passed they are further processed. Draw frame slivers may be semi-combed then again passed through draw frames before they are fed to roving frames (Speed frame).

- Slivers are converted to rovings of specified hank as per spinning plan. Thereafter these roving bobbins are fed to ring frames well set with technological parameters as per spinning plan where they are converted to particular yarn counts to be used for terry towels.

- These ring bobbins are fed to automatic winding machines where the yarn is converted to packages. These winding machines are also ser for different setting required as per spinning plan.

- Whenever double yarns are needed for weaving terry towels the single yarns are processed on TFO machines to convert them to double yarns with defined twist factor and direction of the twist as required for towels.

Preparation of spinning plan is very critical and needs a lot of knowledge and understanding of spinning technology. Application of this spinning plan determines yarn parameters and yarn quality and hence needs a close supervision from process control and quality control laboratory.

Weaving

Warping/Sizing/Drawing-in

Yarn packages are assembled on warping creel as per construction plan, required tensions are set on each yarn package and are processed on sectional or direct warping machines depending on single/double yarns are used.

All machine settings, machine speed is set as per instruction sheets of weaving plan. All warping sets made from single yarns are processed on sizing machines where a starch coating is applied on individual threads to make it weave able on weaving machines. Double yarns sets may or may not be passed through sizing machines. Single sized beams and double sized or unsized beams are taken to drawing in department and beams are drawn as per drawing in weaving plan to make them ready to load on weaving machines.

Loading of beams is high skill jobs which are to be carried out under the close supervision of weaving staff. Before machines are loaded on weaving machines, machines are to be well set, speeds adjusted as per article by experienced, skilled and qualified weaving staff. Use of machine setting sheets as per weaving set plan is essential and important before the machine is set for production. Process control staff and weaving senior staff has to monitor the initial production of few towels and inspect on the machine and off the machine the various parameters of the towel and should exactly match as per weaving plan. Once passed the machine is allowed to go into production.

Mechanism of terry weave in terry fabric manufacturing, two sheets of warp threads run simultaneously, of which, one is kept under normal tension and other is kept under loose tension. The threads of normal tension warp sheet are for ground and threads of loose tension warp sheet are for the pile.

The sequence of operations during weaving for pile formation in 3-pick terry is given below:

- Insertion of the first pick as per the design with loose beating

- Allow a predetermined gap near the feel of cloth

- Insertion of the second pick following the first pick with loose beating

- Insertion of the third pick with heavy beating and bring all the three picks to the fell of cloth.

Pile formation

Pile of the towel plays major role for a towel for its water absorbency and other properties. Loop length is decided by the quality, weight etc. as per requirements. Pile manufacturers use better quality yarn like combed, compact, hydro, zero twisted yarns.

Piles are made by different high-value fibres like superior qualities of cotton suvin, giza, pima, bamboo, modal etc. to get better absorbency and lint properties.

For ground yarn, comparatively coarser counts are used in OE and 2-ply option to give better strength and compactness in ground fabric.

Both piles and ground yarns are prepared in the same manner of warping, sizing, and drawing-in. Like other textile products shirting, suiting, sheeting fabrics, towel making has the same process sequences – desizing, bleaching, dyeing and finishing.

Nano technology – Introduction, Definition, Market, Applications

Factors affecting electrospinning process

Grey inspection

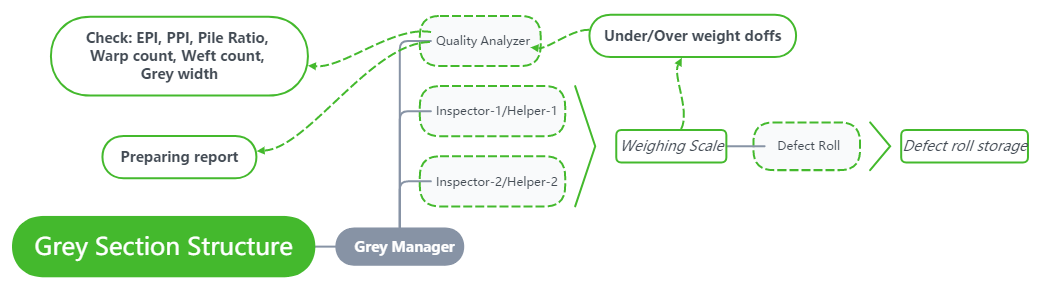

Once towels are manufactured on the looms and their production is monitored through process control the towel roles are cut as per specification sheet and brought to inspection room.

From inspection room storage selected quality rolls passed for quality as per processing plan are dispatched to process house for bleaching and dying operations.

Bleaching

These selected rolls are transported by using recommended trolleys to bleaching section and are bleached in J-Box machine which is a continuous bleaching machine. The fabric is treated with bleaching recipes such as hydrogen peroxide, caustic defoamers and other ingredients.

Reaction time and machine speed have to be set as per process plan prepared after considering all activity factors. After the roll is bleached it is sent to washing machines and washed thoroughly so that no trace of chemicals remains on the fabric. Then these rolls are dried and sent to Dyehouse. All procedural requirements are followed so that the rolls can be identified at any stage during processing and in storage.

Dyeing

As per requirement order from dye house, bleached rolls are transported to dye house for dying operations for various colours as per dye house planning sheets. Dried uncut rolls are taken to Dying machines for dying with vat colour using vat dye receipt. This has proven over time to provide colourfast towelling after extensive residential laundering.

It is sent to washing machines and washed thoroughly so that no trace of chemicals and lose dye particles remain on the fabric. Then these rolls are dried on an air-drying machine and sent to folding cutting/folding and packaging department. All procedural requirements are followed so that the rolls can be identified at any stage to avoid mix-ups during processing and in final storage.

Cutting, folding, and packaging

As per final inspection plan, rolls are transported with special care to finish folding department.

Instruction techniques to follow are for visual inspection

- Step 1: is to open these rolls and are cut as per instruction sheets

- Step 2: is to stitch / ham towels

- Step3: Each towel stitched is inspected by quality inspector attached to a respective table. He has to ensure defect free towel on both sides, the label for passing and sent to final inspection table. The rejected towels are to be kept separately for operational departmental inspection

- Step 4: Final inspection by a senior inspector passed, labelled and sent for final packaging and dispatching. Rejected towels are kept separately.

Quality Control

Quality assurance department plays an important role to monitor, check, and control each manufacturing activities and operations from receiving all raw material to the final dispatch of products. This is controlled through close supervision and active participation of on-line process control and off-line quality control laboratory. Most common defects found in terry towels are…

All Towels manufacturing mills need to have a strong quality assurance department which is capable to coordinate with production line and assist them to provide vital quality productivity information continuously.

All incoming inputs bought for the manufacturing process are thoroughly examined for their quality parameters as laid down by production plan before they are used during manufacturing operations.