Aramid fibre – a modified form of polyamide Nylon

"Aramid" is formed with a combination of words Ar (Aromatic) + amid (Amides)

ARAMID is a synthetic fibre that is produced by spinning a solid fibre from solution. The initial preparation of the polymer is generally achieved by a chemical reaction between the amine group and a carboxylic acid halide group.

Aramid application

Aramid fibre applications are divided into two categories:

- Reinforcement in composites like sports goods, aircraft, military vehicles and many other.

- Fabrics in clothing such as fire protection clothes or bulletproof vests.

More elaborative uses of aramid are:

Carbon Fibre – strong, stiff, & light weight fibres

Properties, process, history, and application of carbon fibres

- Various forms of composite materials

- Sailcloth

- Snowboards

- Protective gloves, helmets, body armour

- Filament wound pressure vessels

- Flame and cut resistant clothing

- Asbestos replacement

- Ropes and cables

- Optical fibre cable systems

- Jet engine enclosures

- Tennis strings and hockey sticks

- Wind instrument reeds

- Reinforcement for tyres and rubber goods

- Circuit board reinforcement

Although every application meets its own requirements, almost all of them share aramid’s major characteristics: high strength, high modulus, high toughness, thermal dimensionality stability, low creep and lightweight.

Advantages

Aramid main advantages are high strength and low weight. Like graphite, it has a slightly negative axial coefficient of thermal expansion, which means aramid laminates can be made thermally stable in dimensions. Unlike graphite, it is very resistant to impact and abrasion damage. It can be made waterproof when combined with other materials like epoxy. It can be used as a composite with rubber retaining its flexibility. High tensile modulus and low breakage elongation combined with very good resistance to chemicals make it the right choice for different composite structural parts in various applications.

Disadvantages

On the other side, aramid has a few disadvantages. The fibres absorb moisture, so aramid composites are more sensitive to the environment than glass or graphite composites. For this reason, it must be combined with moisture resistant materials like epoxy systems. Compressive properties are relatively poor too. Consequently, aramid is not used in bridge building or wherever this kind of resistance is needed. Also, aramid fibres are difficult to cut and to grind without special equipment (e.g. special scissors for cutting, special drill bits). Finally, they suffer some corrosion and are degraded by UV light. For this reason, they must be properly coated.

Major Application of Aramid Fibers

Thanks to the outstanding properties of aramid fibres, they can be used in a wide variety of industries.

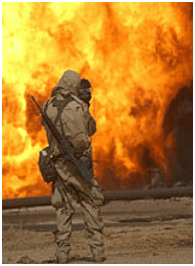

- Flame-resistant clothing: For example, military MIL-G-181188B suits. This includes Heat-protective clothing and helmets.

- Substitute for asbestos (e.g. brake linings), whose fibres will give rise to pulmonary diseases after being inhaled into the lungs.

- Hot air filtration fabrics

- Reinforced thermoplastic pipes

- Bullet-proof wear: Body armour, competing with PE-based fibre products such as Dyneema and Spectra.

- Composite materials and they are often combined with carbon fibre.

- Tires, most recently as Sulfron (sulfur-modified Twaron)

- Mechanical rubber reinforcement

- Ropes and cables, although severe weakening under impact limits its use on boats and climbing. Aramid cables more applicable to static load situations, for example, the cables used as guy-wires for hydro tower erection for Hydro Quebec.

- Wicks for fire dancing

- Optical fibre cable systems

- Sailcloth (not necessarily racing boat sails)

- Sporting equipment

- Drumheads

- Wind instrument reeds, such as the Fibracell brand

- Loudspeaker diaphragms

- Boat hull material

- Fibre-reinforced concrete

- Tennis strings (e.g. by Ashaway and Prince tennis companies)

- Hockey sticks (normally in composition with such materials as wood and carbon)

- Snowboards

- Jet engine enclosures