Carbon Fibre – strong, stiff, & light weight fibres

Properties, process, history, and application of carbon fibres

Carbon fibres are extremely strong, thin fibre, made of aligned carbon crystals with the shape of a honeycomb and consisting of long, chainlike molecules of pure carbon that are made by charring synthetic fibres such as rayon in the absence of oxygen.

The carbon fibres are ideally used where strength, stiffness, lighter weight and outstanding fatigue properties are of critical importance. They are also used where high temperature, chemical inertness and high damping are essential. widely used in commercial and civilian aircraft, recreational, industrial, and transportation markets.

A brief history of Carbon Fibres

Thomas Edison invented the electrical bulb during 1879 and he used cotton threads/bamboo slivers at very high temperatures in an enclosed glass tube which cuts off oxygen supply and threads were backed which carbonized them into carbon fibre filament. Roger Bacon was the first to create the carbon fibre from polyacrylonitrile (PAN) during 1958 and discovered its tensile strength.

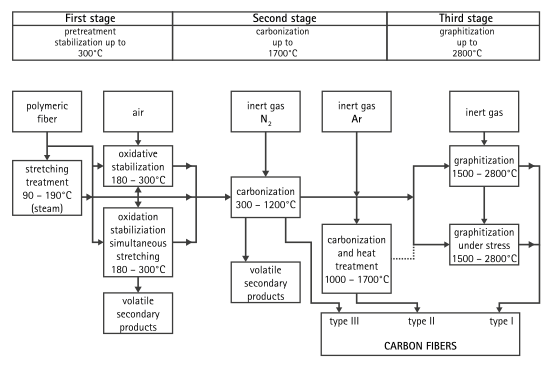

About 85 to 90% of fibres are made from polyacrylonitrile and remaining are made from rayon or petroleum pitch. All of these materials are organic polymers, characterized by long strings of molecules bound together by carbon atoms.

Aramid fibre – a modified form of polyamide Nylon

"Aramid" is formed with a combination of words Ar (Aromatic) + amid (Amides)

US Airforce and NASA began using carbon fibre for its applications to aircraft and spacecraft. Carbon fibre and Kevlar fibres are materials that are used for making bulletproof vests protective inserts etc. They are known to be the most composite materials along with glass fibres and are strong and functions extremely well.

In comparison, steel has a tensile modulus of about 29 million psi (200 million kPa) thus, the strongest carbon fibres made are ten times stronger than steel and eight times that of aluminium, and are much lighter than both materials, 5 and 1.5 times respectively.

DEFINITION OF CARBON FIBER

- A material consisting of thin, strong crystalline filaments of carbon, used as a strengthening material, especially in resins and ceramics.

- a very strong lightweight synthetic fiber made especially by carbonizing acrylic fiber at high temperatures; also: a material made from such fibers embedded in a resinous matrix

- a strong, stiff, thin fiber of nearly pure carbon, made by subjecting various organic raw materials to high temperatures, combined with synthetic resins to produce a strong, lightweight material used in construction of aircraft and spacecraft.

I felt exceptionally cheerful while perusing this site. This was truly extremely instructive site for me. I truly enjoyed it. This was truly a sincere post. Much obliged!.

www.roaches.co.uk/textile-...indale-rub-test