Introduction to breathable water-repellent textiles and their production methods

Type of Breathable textile materials | Methods of producing Breathable textiles

Breathability refers to the ability of a fabric to absorb moisture and release it through the material itself, allowing it to ‘breathe’. Breathable Fabrics transmit body moisture away from the body, thus maximizing comfort and dryness during outdoor activities.

Fabric Production process and coating techniques

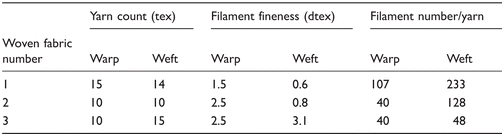

Fabric requirements need tendency of to resist wetting is a function of the chemical nature of the solid surface, the roughness of the surface, the porosity of the surface, and the presence of other molecules on the surface. Woven fabrics for water repellent/ water resistant/breathable textiles feature permeable pore channels between yarn interlocking points (mesopores), which create an increased risk of penetration by contaminated fluids and particles. These pore channels can be reduced in size by finer count and high-density weaving.

This, however, results in deteriorated drapability and performance characteristics. The barrier properties of the woven fabric are determined by the construction-dependent pore morphology (mesopores and micropores), and the surface character of the textile structures.

When used for protective garments, it is equally important to guarantee high wearing comfort. Fulfilling these conflicting requirements (barrier effect and comfort) in a single textile structure is an immense challenge. To impede the penetration or pervasion of fluids, barrier textiles are finished with fluorocarbon (FC) resin.

The hydrophilizing by means of FC also reduces the adsorption of water on the fibers. Such woven fabrics only have an effective barrier function against fluids at small amounts of fluid, low pressures, and short exposure times. In the simplest case (sieve effect), the maximum pore sizes present in the woven fabric determines particle retention. In the case of smaller particles and larger pores, further barrier mechanisms are known, such as retention by bridging and by adhesive forces (van der Waals forces), or by electrostatic forces.

In microfilament woven fabrics, deep-bed filtration also plays an important role. Particles penetrating into the woven fabric interact with the filament surfaces and can be deposited between the woven fabric filaments. In order to fully exploit the advantages of woven fabrics as barrier textiles (good drapability, high wearing comfort), mesopores present primarily at the crossing points of warp and weft yarns in the woven fabric are to be reduced in size by a targeted finishing with fine microparticles so that the woven fabric meets the stated requirements.

Thank you for the detailed explanation Mr. Ashok Haboo. It has been very helpful for a new merchandiser like me. I have recently started a textile startup called

swagswami.comSwag Swami and we are in the process of developing new breathable activewear for the Indian Market. This article has helped me a lot!Thank you once again Sir!