Introduction to breathable water-repellent textiles and their production methods

Type of Breathable textile materials | Methods of producing Breathable textiles

Breathability refers to the ability of a fabric to absorb moisture and release it through the material itself, allowing it to ‘breathe’. Breathable Fabrics transmit body moisture away from the body, thus maximizing comfort and dryness during outdoor activities.

Coating Methods

-

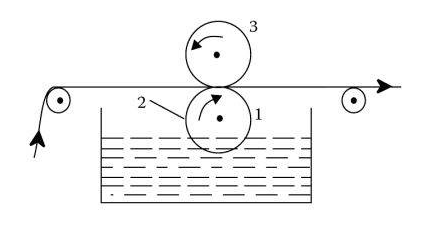

Knife Coating (floating knife) or Direct Coating

In Knife Coating, as seen in Figure 3, the liquid coating is applied to the fabric while being run at tension under a floating knife blade, the distance between the fabric and the knife blade determines the thickness of the coating. The blade can be angled and have different profiles to affect the coverage. For this process to be effective the liquid coating must be quite viscous in order to prevent it from soaking through the fabric, the coating is then dried or cured.

This technique is best used for Filament yarns as the staple fibers in spun yarns can protrude on the surface creating an uneven finish, but this is dependent upon the thickness of the applied coating. For this type of coating to be most successful the weave structure has to be quite tight and the fabric capable of being held taught.

![breathable-fabrics-knife-coating]()

Figure 3. Fung, W, 2002, Coated and Laminated Textiles, UK; Woodhead Publishing; -

Direct Roll Coating

In this process, the coating liquid is rolled onto the fabric by a roller suspended in the coating solution, often a blade is positioned close to the roller to ensure not too much coating solution is applied.

![breathable-fabrics-direct-roll-coating]()

Figure 4. Direct Roll Coating from;Sen, A K, 2008, Coated Textiles; Principles and Applications, 2nd Edition, USA;Taylor and Francis. -

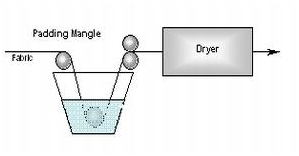

Pad-Dry-Cure

Also referred to as Padding, this technique, widely regarded as a textile finishing technique, can, in fact, be used to add a variety of coatings, but this usually refers to a fiber coating for the application of micro or nanomaterials or chemical compositions.

As shown in figure 5, the fabric is submerged in the coating solution then the excess squeezed out in the rollers, which dictates the pick-up percentage, the fabric is then dried and cured.

![breathable-fabrics-pad-dry-cure]()

Figure 5 -

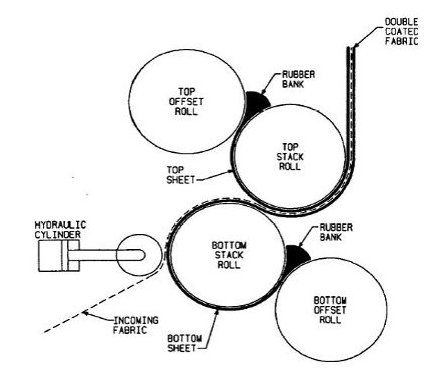

Calender coating

Calender finishing involves the fabric passing through a set of heated rollers to singe off any surface fibers and add lustre and smoothness. Calender coating is the same principle in which the fabric passes through heated rollers, but through this process, a coating is applied as demonstrated in figure 6. This image demonstrates the simultaneous coating of both sides of the fabric with the thickness of the coating determined by the width of the nip in-between the rollers, more rollers used can provide a thinner coating.

![breathable-fabrics-calendar-coating]()

Figure 6. Depicts calender coating. Image from; TPO coated PP fabrics and their applications -

Hot melt extrusion coating

Hot melt extrusion coating is applied in the same process as calendaring with the coating being melted from granules fed to heated rollers which then nip the coating to the fabric. It is used to produce un-supported films and these freshly produced films are added directly to the fabric. Its uses are mainly for Thermoplastic polymers such as Polyurethane, Polyolefins, and PVC.

-

Foam Finishing

Foam finishing was developed as a more environmentally friendly version of the pad-dry-cure system, as the chemical applied requires less product in weight, but equates to a high surface area. Foam also ensures lesser wetting takes place, which requires less drying; furthermore, waste is reduced in terms of residual liquor. This technique is useful in coating heavy fabrics such as carpets and can be used to effectively coat only one side.

Thank you for the detailed explanation Mr. Ashok Haboo. It has been very helpful for a new merchandiser like me. I have recently started a textile startup called

swagswami.comSwag Swami and we are in the process of developing new breathable activewear for the Indian Market. This article has helped me a lot!Thank you once again Sir!