Weaving Loom Mechanisms

The basic mechanisms in any type of looms can be classified into Primary (shedding, picking & beat up), secondary and Auxiliary motions. Shedding opens the warp sheet into layers. The picking causes the shuttle carrying weft to be propelled from one end of the loom to another. The beat-up motion lays the previously laid weft to the fell of the cloth. The secondary motion comprises of take-up and let-off motions. The auxiliary motions consist of the warp stop, weft stop, and warp protector motions.

Evolution of Looms

A loom is a device that causes interlacement two sets of threads, namely, warp and weft threads, to form a fabric. The very first loom in history is the pit loom. Subsequently, the handloom was developed and then the power loom.

After the advent of power looms, a number of developments have taken place. The very first power looms that had been developed were of the non-automatic type. These looms had neither a positive let-off device nor warp stop mechanism or a weft changing mechanism. This demanded a great deal of attention from the weaver.

The semi-automatic loom was then developed which incorporated two out of the above three mentioned mechanisms. Then the automatic loom was developed which had all the three essential mechanisms, namely, positive let-off device, warp stop mechanism, and weft replenishment mechanism. The last century saw the development of shuttleless weaving mechanisms.

Loom Mechanisms

A loom is a device that causes interlacement two sets of threads, namely, warp and weft threads, to form a fabric.

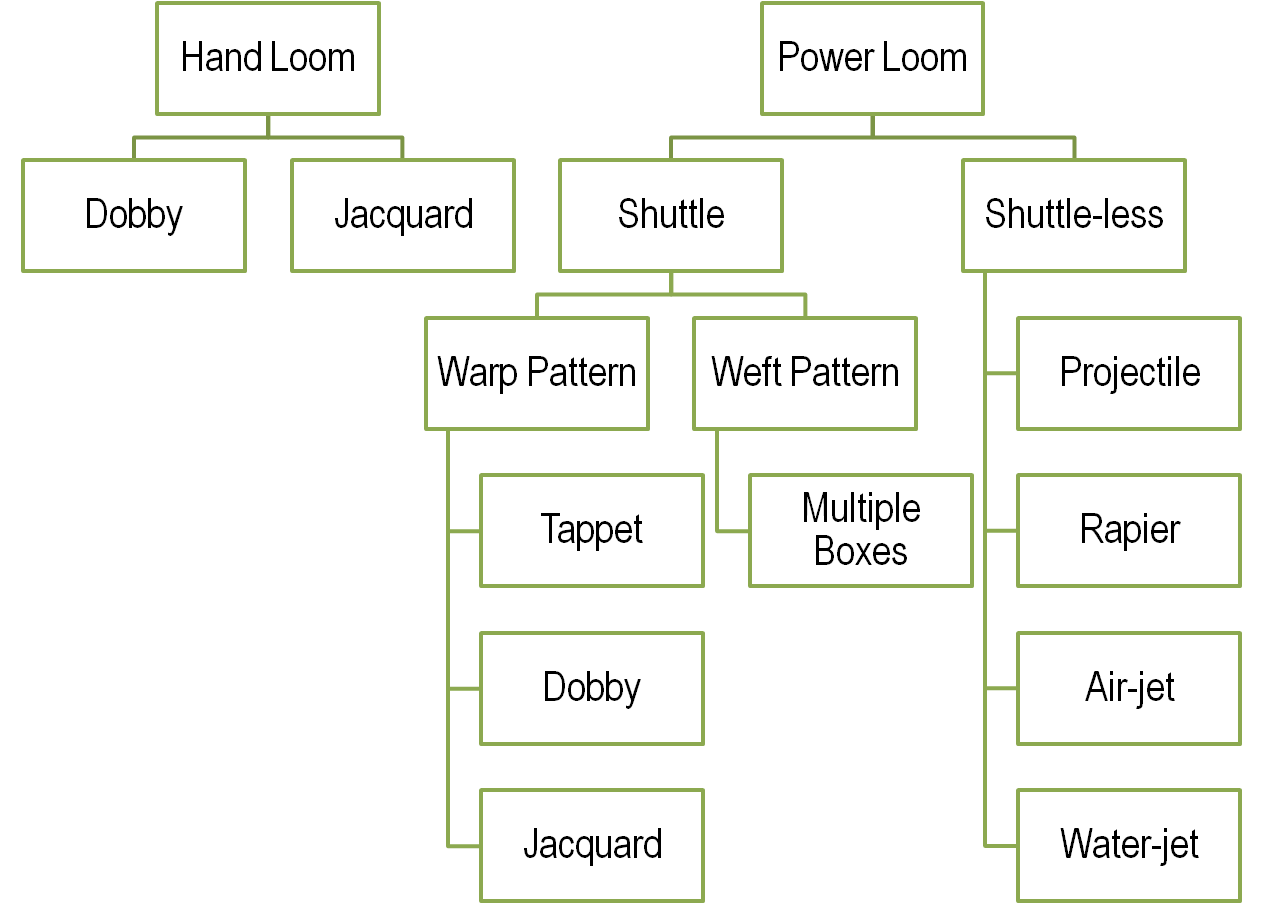

Classification of Looms

The basic mechanisms in any type of loom can be classified as follows:

The hand loom was operated by the weaver using his hands to propel the shuttle from one end to another. The weaver used his foot to operate the healds. The production in this type of loom was obviously very less and thus varied from weaver to weaver

The power loom was operated by power. This reduced the strain of the weaver. Considerable automation has taken place which resulted in lesser strain of the operatives and increasing the production and efficiency of the loom. The shuttle less looms are good examples

The tappet, dobby and jacquard are warp patterning mechanisms. Among the shuttle looms, the tappet loom is the simplest. It is suitable for weaving up to 8 heald shafts. The dobby loom is suitable for figuring upto 40 heald shafts and the jacquard is suitable for elaborate designs running to several picks. The advantage of the jacquard mechanism is that it can control individual warp ends and hence has a large figuring capacity.

- Primary motions

- Secondary motions, and

- Auxiliary motions.

The primary motions can further be divided as shedding, picking and beat up motions. The shedding opens the warp sheet into layers to facilitate passage of shuttle. The picking motion causes the shuttle carrying weft to be propelled from one end of the loom to another. The beat-up motion lays the previously laid weft to the fell of the cloth.

The secondary motions comprise of take up and let off motions. The take-up motion helps to wind the cloth on to the cloth roller and also influences the pick density in the cloth. The let-off motion helps to let the warp from the weaver’s beam at a uniform rate thus maintaining the warp tension constant throughout the weaving process.

The auxiliary motions consist of the warp stop motion, weft stop motion and warp protector motion. The warp stop motion is used to stop the loom in the event of warp breakages. This is necessary to prevent fabric defects such as missing ends and floats. The weft stop motion is used to stop the loom in the event of weft exhaustion or weft breakages. This is necessary to prevent missing weft threads called cracks, in the fabric. The warp protector is used to prevent multiple warp thread breakages in the event of shuttle getting trapped in the middle of the warp sheet.

Classification of Looms

Looms can be classified as follows depending on whether they use a shuttle or not and the method used to insert the weft yarn.

| Loom type | Method of inserting weft yarn | Characteristics | |

|---|---|---|---|

| Looms with shuttles | The weft yarn is inserted through the back-and-forth motion of the shuttle. | Great all purpose loom. Vibration and noise are severe problems and high-speed operation is difficult. | |

| Looms without shuttles | Gripper loom | A small metal gripper shuttle grasps the weft yarn and inserts it. | A very versatile loom, but it is noisy and there is a limit to its operation at high speed. |

| Rapier looms | Two bands at the center of the fabric receive and passes on the weft yarn. The catch method is the most popular method and is further broken down into two types, the band method, and the pole method. | A very versatile loom, but it is noisy and there is a limit to its operation at high speed. | |

| Water jet looms | A jet of water is used to insert the weft yarn. | High-speed operation is possible. Since water is used only filament yarns (synthetic fabrics) can be woven. | |

| Air jet loom | A jet of air is used to insert the weft yarn. | High-speed operation is possible. At present this is the most popular type of loom and its functions are excellent overall. | |

I would to be described about those threeemechanisms at a time