Types of Pressing machinery and equipment

Ironing and pressing machines are vital components of the garment industry, contributing significantly to the quality, appearance, and efficiency of clothing production. Understanding the various types of machines, their functions, and their applications is essential for garment manufacturers to make informed decisions and optimize their production processes. Whether it’s achieving wrinkle-free finishes, customizing garments with graphics, or ensuring the precision of seams and creases, the right ironing and pressing machine plays a pivotal role in delivering high-quality clothing items to consumers. As the garment industry continues to evolve, these machines will remain indispensable tools, driving innovation and excellence in garment manufacturing processes.

The garment industry relies heavily on a range of specialized machines to ensure that clothing items meet the highest standards of quality and appearance. Among these machines, ironing and pressing machines are integral to achieving the desired finish, removing wrinkles, and giving garments their final polished look. In this comprehensive essay, we will explore the various types of ironing and pressing machines used by the garment industry, their functions, and the critical role they play in the production process.

There are hundreds of different types of pressing machines on the market because of the variety of garment types produced, each with its own specific pressing requirements. Here are the respective of there types.

High tech pressing machine for men’s and women’s clothing is a digital programmer and presses the shoulder, sleeve head and sleeve cuff in one set-up.To sum up it is no exaggeration to say that a part of cutting, the two cornerstones of garment quality are fusing and pressing. The pressing processes give the final finish and appearance. The importance of pressing should never be underestimated, because of its decisive contribution to garment quality and appeal.

The Significance of Ironing and Pressing Machines

Ironing and pressing machines are indispensable in the garment industry, as they contribute significantly to the overall quality and appearance of clothing items. These machines are responsible for:

Wrinkle Removal Ironing and pressing machines effectively remove wrinkles and creases from fabrics, leaving garments with a smooth and polished appearance. This step is essential to ensure that clothing items look neat and presentable to consumers.

Seam Pressing Seam pressing is a critical function performed by these machines. It ensures that seams are flat and well-defined, contributing to the durability and appearance of the garment.

Fabric Finishing These machines are used for fabric finishing, which includes tasks like setting pleats, shaping collars and cuffs, and achieving the desired texture and drape of the fabric.

Application of Heat Transfers In addition to pressing and ironing, some machines are used for heat transfer applications, such as applying logos, graphics, or labels onto garments. This is common in the production of branded and customized clothing.

Types of Ironing and Pressing Machines

There are several distinct types of ironing and pressing machines used in the garment industry, each tailored to specific tasks and requirements. Understanding these types is essential for garment manufacturers to select the appropriate equipment:

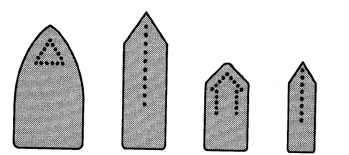

Steam Irons

Steam irons are among the most common types of ironing machines used in the garment industry. They utilize steam to remove wrinkles and creases efficiently. Steam irons come in various sizes and capacities, making them suitable for a range of production scales, from small workshops to large factories.

Steam Presses

Steam presses are larger and more powerful than steam irons. They are equipped with a larger pressing surface and higher steam output, making them ideal for bulk pressing tasks. Steam presses are often used in industrial garment factories to achieve consistent and professional results.

Vacuum Ironing Tables

Vacuum ironing tables are designed with a built-in vacuum system that creates suction, holding the fabric in place during the ironing process. This ensures that the fabric remains taut and flat, resulting in wrinkle-free and precise ironing. Vacuum ironing tables are commonly used in tailoring shops and small garment production units.

Shirt Pressing Machines

Shirt pressing machines are specialized for pressing shirts and blouses. They are equipped with shaped pressing bucks that mimic the shape of a shirt, allowing for efficient and precise pressing of collar, cuffs, and front panels. These machines are essential in garment factories specializing in formal and dress shirts.

Trouser Pressing Machines

Trouser pressing machines are designed for the efficient pressing of trousers and pants. They feature specialized bucks and forms that ensure creases are sharp, and the garment maintains its shape. These machines are crucial in achieving a polished appearance for trousers in the garment industry.

Fusing Machines

Fusing machines are used for fabric bonding using heat-activated adhesives. They are employed in garment manufacturing to attach interlinings, labels, and patches securely to clothing items. Fusing machines ensure a strong and durable bond while maintaining the fabric’s integrity.

Heat Transfer Presses

Heat transfer presses, also known as heat presses, are essential for applying graphics, logos, and designs onto clothing items. These machines use heat and pressure to transfer ink or other materials onto fabric, creating custom and branded apparel.

Automated Pressing Machines

Automated pressing machines are advanced equipment used in large-scale garment production. They are capable of automated pressing, ironing, and folding, significantly increasing efficiency and productivity in garment factories.

Applications of Ironing and Pressing Machines

The application of ironing and pressing machines varies depending on the type of machine and the specific needs of the garment industry. Let’s explore how each type of machine is commonly used:

Steam Irons and Steam Presses Steam irons and steam presses are versatile and widely used for:

- Ironing and finishing garments to remove wrinkles and creases.

- Pressing seams for a polished and neat appearance.

- Setting pleats, darts, and folds.

- Preparing garments for labeling and heat transfer applications.

Vacuum Ironing Tables Vacuum ironing tables are used for:

- Precision ironing of delicate fabrics and details.

- Achieving wrinkle-free results.

- Holding fabric in place during ironing for consistent results.

Shirt and Trouser Pressing Machines Shirt and trouser pressing machines are specialized for:

- Pressing dress shirts, blouses, and formal shirts.

- Ensuring sharp creases and polished appearance.

- Efficiently handling high volumes of specific garment types.

Fusing Machines Fusing machines are employed for:

- Bonding interlinings, labels, and patches to garments.

- Ensuring strong and durable attachments.

- Enhancing the structural integrity of clothing items.

Heat Transfer Presses Heat transfer presses are crucial for:

- Customizing clothing items with graphics, logos, and designs.

- Producing branded apparel for promotional purposes.

- Adding value to garments through customization.

Automated Pressing Machines Automated pressing machines are used for:

- High-volume and large-scale garment production.

- Streamlining the pressing and finishing process.

- Increasing productivity and reducing labor costs.

Factors Influencing Selection of Pressing Machines

Selecting the appropriate ironing and pressing machine is a critical decision for garment manufacturers. Several factors influence the selection process:

Production Scale The scale of production, whether small-scale, medium-scale, or large-scale, determines the capacity and type of machine required.

Garment Types The specific types of garments being produced influence the choice of machines. Different garments have unique pressing and ironing requirements.

Fabric Types The nature of fabrics being used, such as delicate silks or heavy denim, affects the choice of machines. Different fabrics may require different temperature settings and pressing techniques.

Precision and Quality Industries like formalwear or high fashion demand precision and high-quality finishes, necessitating specialized machines.

Automation and Efficiency Modern garment factories often opt for automated pressing machines to improve efficiency and reduce labor costs.

Cost Considerations Budget constraints play a role in selecting machines. Businesses must balance their need for quality with their available resources.

Maintenance and Safety

Regular maintenance and safety protocols are crucial for the safe and efficient operation of ironing and pressing machines. Proper cleaning, calibration, and safety measures are necessary to prevent accidents and ensure the longevity of the equipment.