Bhagalpuri Silk Fabric Weaving Process

Bhagalpuri silk is a facet of the timeless heritage of Bihar, made with painstaking details of perfection. Bhagalpur silk known as the ‘queen of the silk’ has superior fine quality giving it a rich and delicate feel, is now available in various vibrant colours and prints. Bhagalpuri silk is one of the most refined forms of silk fabric.

Bhagalpuri silk or Tassur silk is very popular around the world for its products like silk sarees, shawls and suits. Bhagalpuri silk derives its name from a small town situated in Bihar called Bhagalpur. Bhagalpur has a long history of silk crafts, whose traditions have been passed on to generations.

Extraction of Threads from the Cocoon

The process of making Bhagalpur silk fabric from fibre to fabric has been explained below.

- The sorted, undamaged cocoons are boiled in hot water with a pinch of baking soda for an hour or two, to soften them and dissolve the sericin gum to facilitate the process of unwinding the fibres from the cocoon.

- The threads are meticulously reeled from the cocoons individually in long threads. Then they are wounded on the bamboo spools. The bare thighs are used by employees to draw out one filament of silk from the cocoons. This silk is Ghicca silk. In khewa silk, the hands are utilized by the workers to unwind the silk filament.

- After completion of this process, the spools are transferred to skeins. After drying, these skeins are reeled on bobbins which form a thicker, stronger and multi-threaded yarn. This process is called throwing.

Dyeing of Silk Yarn

Steps to dye the silk yarn are explained below:

- Traditionally natural dyes are used for the process. Before dyeing the silk threads are bleached and dried.

- The dyes are extracted by boiling them and putting yarn skeins. The solution is strained, and therefore the dye is applied to wet yarn skeins.

- After some time, the skeins are put in a mordant solution to make fast the effect of the dye for 5 mins Kasis stone is used as the mordant in this process. The yarn is washed with reetha powder.

Weaving Process

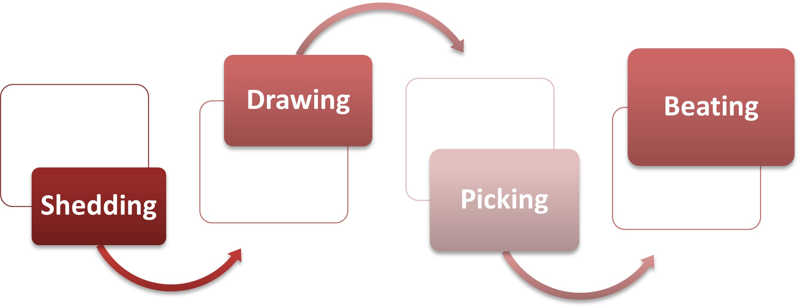

In the weaving process on the loom, the warp beam is mounted at the rear and also the warp yarns are conveyed to a cylinder called the cloth roll, which is at the front of the loom. Supported on the loom frame between the 2 cylinders, the warp yarns are able to be interlaced by the filling or weft yarns, to supply the woven fabric. In the weaving process, four steps are fundamental.

- Shedding: This operation is performed by the harnesses – rectangular frames to which a series of wires, or heddle, are attached. Each warp yarn comes from the beam, must be pass through an opening in the heddle.

- Drawing in: In the operation of drawing each warp yarn through its appropriate heddle eye. The heddle frame raises or lowers certain groups of alternate warp yarn by treadles so that the filling yarns alternate in passing under one group of warp yarns and over another in the weaving process.

- Picking: Because the harnesses raise the heddles, which successively raise the warp yarn, the filling yarn is inserted through the shed by the shuttle that contains a bobbin of filling yarn. This crossing of wefts between the shed of the warp is called Picking. All warp yarn passes through a heddle eyelet and through an opening in another frame that looks like a comb. This is known as a reed. The filling yarn is pushed against the woven fabric with each picking operation. This process is known as picking.

- Beating: The newly constructed fabric must be wound on the cloth beam with each shedding, picking and beating. This is referred to as taking off.

Finishing

After the fabric is taken off the loom, it’s washed with plain water and spread for drying. After the process of drying, water is sprinkled with a spray machine. The spraying must be uniform all over the surface. Then the fabric is folded properly and beaten with a heavy hammer, called kundi. It is an indigenous process that sets the weave properly. The fabric is now ready for calendaring. This is a mechanically produced finish, achieved by pressing the fabric material between a series of two or more rollers to smoothen it and produce a wrinkle-free effect.

Conclusion

Bhagalpuri silk is one of the apt representations of the rich heritage of Indian handlooms. The Bhagalpuri silk is the outcome of the arduous labour and exquisite workmanship of the weavers. The process of making the silk from fibre to fabric is an intricate and delicate process. The livelihood of the weavers depends completely on this craft, hence for the upliftment of the weavers and to sustain the existence of the craft, it is crucial for craft to gain recognition from the consumers, and to know about the process behind it.

Contributors

Akriti Pandey

Khushi Gupta

Mansi Chand

National Institute of Fashion Technology

(Semester6, Department of Fashion Technology, Patna)

Nilima R. Topno

National Institute of Fashion Technology

(Associated Professor, Department of Fashion Technology, Patna)

Bibliography

How is silk made? A step by step guide. (n.d.). Retrieved from Biddle Sawyer Silks: https://www.biddlesawyersilks.com/how-is-silk-made-a-step-by-step-guide/

Yarn Yarn . (2021). Retrieved from https://www.yarnyarn.co.uk/blogs/news/organic-silks-and-tassar-silk-handspun-chunky-wild-silk-yarn

HI SIR MERI EK SHOP HE SURAT ME MUJE AP SE BOHAT KUCH SIKHNE KE LIYA SAVAL KRNE HE OR MERE BUSSINESE KE LIYE PUCHNA HE