3D Body Scanning

Anthropology and Sizing (APD)

Types of 3D Body Scanning

Laser 3D Body Scanning

This technology consists of using laser rays to project into the human body. Light sensors capture the measurements. A laser beam scans the consumer’s body in a fraction of a second. It is contact-free and does not have any health hazards. The scanner uses low power microwaves to illuminate the human body. These waves easily penetrate the clothing and reach the person’s body. To avoid offensiveness of the light beam only eye-safe lasers are used. The computer software then analyzes the high-resolution pictures of the human body and decides the exact tailoring measurements for that individual. Within seconds, hundreds of measurements are taken from head to toe to create the exact 3D data. The scan takes hundreds of individual measurements, despite only a few will be used when tailoring the garment.

Procedure

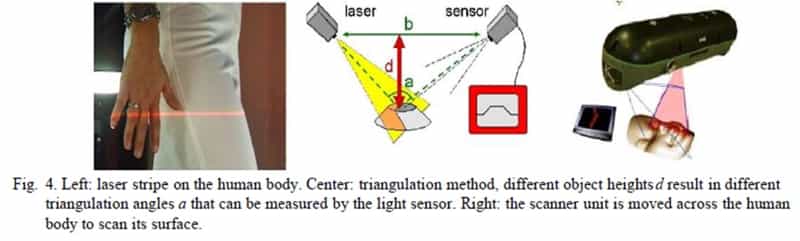

Laser scanning technology consists of using lasers to project onto the human body one or more thin and sharp stripes. Simultaneously, light sensors acquire the scene and by applying simple geometrical rules the surface of the human body is measured. To assure the inoffensiveness of the light beam, only eye-safe lasers are used. Special optical systems and mirrors are used for the generation of stripes from a single laser light beam. The laser scanner unit, which is composed of the laser, the optical system and the light sensor, is moved across the human body to digitize the surface.

The type of movement and the number of employed units can vary depending on the human body part to be measured.

- For example, the full-body scanner of Vitronic1 (Figure 5 left) consists of three scanner units that move vertically synchronously along three pillars.

- A second example is the head scanner of Cyberware2 (Figure 5 centre). In this case, a unique scanner unit moves in a circle around the head of a person.

- As the last example is shown the foot scanner of Vorum Research Corp.3: the scanner is composed of three units, which moves horizontally, two laterally and one from the bottom (Figure 5 right).

Disadvantages

- The high costs for the production of hardware components for the laser scanning technology have to be considered a disadvantage.

- Additionally to the laser, the light sensor and the optical system, also precise electric motors have to be used for the displacement of the scanner units. Moreover, the complete scanning system has to be calibrated so that the geometrical disposition of all the elements can be determined exactly.

- Another disadvantage of this method is the time required for the digitization of large surfaces. There is no problem with the measurement of extremities like feet and hands since these body parts can be kept immobile for some seconds. But, in the case of the measurements of the head or full body, it is practically impossible to stay immobile for several seconds. Uncontrolled movements as breathing or muscle contraction can generate errors.

White-light 3D Body Scanning

This system uses a white light-based scanner and measurement extraction software. Hundreds of images are captured and automatically accurate measurements are extracted through the software.

A series of light fringes are projected into the individual whose measurements need to be taken. 3D information is acquired by analyzing the deformation that the projected light reflects after touching the consumer’s body. An integrated camera captures the series of images and exhibits the series of deformation in the reflected light. The projection and image formation takes only a few seconds. From these images the measurements of the surface of the object, that is the consumers’ measurements are obtained.

- Instead of moving the scanner unit, a light pattern(usually in form of stripes) is projected onto the human body (Figure 6 left). A light sensor (e.g. a digital camera) acquires the scene.

- The scanning device is composed usually of a pattern projector and a light sensor (Figure 6 centre). More complex systems use two or three light sensors. The measurement process is similar to the method of laser scanning: stripes on the surface are measured singularly by using triangulation.

- Usually, binary coding systems (Figure 6 right) are used to determine the origin of the single stripes; for the increment of the resolution, the projected stripes are additionally shifted.

Different patterns are employed by the different manufactures. Figure 7 give some examples of possible variations of the Classic binary code.

What is the difference between white light body scanning and Laser scanning?

- The white light body scanning method is superior to laser technology in a way that data capture happens in a very short time period and also digitization of the entire surface parts are made possible.

The major difference to laser scanning is that the acquisition happens in a very short time and that it results in the digitization of entire surface parts. Everything happens in a short time period (mostly under one second) so that human bodies can be digitized without problems: the uncontrolled movements of the person are not a problem.

However, the field of measurement of such scanning devices is limited, e.g. Capturor of InSpeck4 (Figure above) can measure surfaces with maximal size of half part of the human body (e.g. upper torso). To measure large parts of the human body (e.g. entire head, full-body) multiple scanning devices are required.

Disadvantages

This procedure has the disadvantage, that multiple units cannot be used simultaneously since they interfere with each other’s light patterns projections. Practically, this means, that multiple types of equipment have to be used serially. This implies again an extension of the acquisition time.

- The disposition and the number of employed sensors and projectors can vary depending on the human body part to be measured. For example, the face scanner of Breuckmann5 (Figure 8 left) consists of one projector and two cameras that acquire both sides of the face of a person.

- A second example is the face scanner of IVB Jena6 (Figure 8 centre). In this case, a mirror system is employed to project the light pattern from five directions by using a single projector; five cameras acquire the different scenes.

- As the last example is shown the full-body scanner of InSpeck4 (Figure 8 right): the scanner is composed of three pillars, each having two units, each composed of a camera and a projector.

Combination of Modelling and Image Processing

In this process, 3D measurements are not used, but 2D images are used to extract and generate 3D information. Three images of the person, two from the front and one from the side in acquired, and measurements are calculated based on the body silhouette. They produced computer models that are very realistic. The big advantage of combining image processing and modelling techniques is that it is less expensive when compared to the other two ways of processing. Two examples are described to explain this technique:

![]() The 2D full-body scanner Contour of Human-Solutions (Figure 9 left), the first example, three images of a person are acquired (two from the front and one from the side). By using the symmetry of the human body, the most important sizes of the body are computed with sufficient accuracy from the silhouettes of the body. The extracted body sizes are used, in this specific example, for the production of made-to-measure dresses.

The 2D full-body scanner Contour of Human-Solutions (Figure 9 left), the first example, three images of a person are acquired (two from the front and one from the side). By using the symmetry of the human body, the most important sizes of the body are computed with sufficient accuracy from the silhouettes of the body. The extracted body sizes are used, in this specific example, for the production of made-to-measure dresses.

- The face modeller FaceGen of Singular Inversions8 (Figure 9 right), the second example shows the possibility to generate extremely realistic face models by using only two images of the person (from the front and from the side). The 3D computer model is generated manually with the help of user-friendly software tools. In this case, a real measurement of the human face is not performed. However, the produced 3D computer models are extremely photorealistic and completely adequate for applications as, for example, animation and computer games.

Other Active Sensors

In recent years, new technologies based on active sensors have been applied also for the measurement of the surface of the human body. A very interesting product resulted by applying cylindrical holographic imaging technology onto the human body, allowing to perform a whole-body scan while the person remains fully clothed.

In this case, the active sensor uses non-harmful, ultrahigh-frequency radio waves to obtain accurate body measurements. A millimetre-wave array/transceiver illuminates the human body with extremely low-powered millimetre waves. The radiation penetrates clothing and reflects off the body. The reflected signals are collected by the array/transceiver and analyzed by an image processing computer.

- The company Intellifit Corporation translated this technology into a complete solution to extract 3D human body measurements for custom fit applications. Intelligent System (Fig. 10 left) is composed of the 3D scanner based on the millimetre-waves technology and the accompanying software. The scanning process works in the following way: a person steps inside the Intellifit cabin without undressing, the “L” shaped millimeter-waves transceiver swings around and over the person to acquire the required data. The entire scanning process lasts about 10 seconds and the collected data consists of about 200’000 points on the surface of the human body. Out of the measurements, automatic algorithms determine about 200 characteristic body sizes of the human body with an accuracy of about 6mm.

- A second technology based on other active sensors is also exploited for the measurement of the external surface of the human body. In this case, 3D cameras employ special CMOS sensors where each pixel measures the distance to the imaged surface part. Different manufactures are present in the market.

-

![]()

3D camera of CSEM10 These cameras are based on the phase-measuring time-of-flight (TOF) principle. A light source (in this case, an array of emitting diodes) emits a near-infrared wavefront that is intensity-modulated. The light is reflected by the scene and imaged by an optical lens onto the dedicated 3D sensor. Depending on the distance of the target, the captured image is delayed in phase compared to the originally emitted light wave. Measuring the phase delay, the distances of the complete scene can be determined. The result of the acquisition is a depth map of the scene. The core of such cameras is the CMOS sensor.

In fact, the 3D measurement method based on TOF is integrated into the CMOS sensor. Each pixel of the sensor is constructed to measure the phase difference between the emitted light source and the captured returning light. The result is real-time 3D images of the recorded scene. The actual CMOS technology limits the sensor size to about 25K pixels. For this reason, to time, these sensors can be exploited only for few applications regarding the human body, as for example in security (surveillance) or automotive(recognition of pedestrians).

The 2D full-body scanner Contour of Human-Solutions (Figure 9 left), the first example, three images of a person are acquired (two from the front and one from the side). By using the symmetry of the human body, the most important sizes of the body are computed with sufficient accuracy from the silhouettes of the body. The extracted body sizes are used, in this specific example, for the production of made-to-measure dresses.

The 2D full-body scanner Contour of Human-Solutions (Figure 9 left), the first example, three images of a person are acquired (two from the front and one from the side). By using the symmetry of the human body, the most important sizes of the body are computed with sufficient accuracy from the silhouettes of the body. The extracted body sizes are used, in this specific example, for the production of made-to-measure dresses.