How To Improve The Air Permeability Of Fabric?

Did you ever note that certain clothes feel airy and cool while others make you feel as if one is in a suffocating house? But it is how air can freely pass through them. Yeah, these fabrics are endowed with this quality called air permeability which shows how easily air can travel through it. This is similar to wind passing through a window – some materials let it go quietly but others act like a closed door.

In this article, we will be learning how to improve the breathability of fabric making it more comfortable. So let’s jump right in and find out why our favorite textiles are so light!

What Are The Two Types Of Air Permeability Tests?

To understand how fabrics work with airflow, determine their ability to breathe, and provide comfort, air permeability tests are vital! These tests assess whether a fabric lets the air go through or tends to block it thus affecting the wearer’s comfort. Two main types of air permeability testing exist: the Gurley method and the Frazier method.

The Gurley Method:

The Gurley method is a technique used to determine the time taken for a given volume of air to pass through a known cross-sectional area of fabric by applying constant pressure. Let’s look at how it works:

- Two flat surfaces are brought together tightly to hold the fabric sample.

- An equal amount of air is made to move through the material by applying continuous pressure.

- The timer will start once there is airflow and stop as soon as the predetermined quantity of air has passed through the cloth.

- The duration this air required moving along its path over some time is indicated and helps in calculating the amount of air that can be moved through this particular clothing.

This procedure most specifically remains important while evaluating materials with relatively less permeability such as paper and nonwoven fabrics whose importance lies in product development for quality control.

The Frazier Method:

Nevertheless, the Frazier method measures how fast airflow is moving under a fixed pressure drop across the fabric sample. There are various ways in which it differs from the Gurley method.

- To do this, a sample of fabric is placed inside a test apparatus and some area is exposed to airflow.

- A constant pressure difference caused by either a fan or vacuum pump across the fabric causes air to flow through it.

- The airflow rate is measured using a calibrated flowmeter or similar device that quantitatively evaluates the permeability of fabrics.

- The constant pressure drop through fabrics ensures that any differences in samples can be accurately assessed.

Frazier’s approach is commonly used in assessing the air permeability of textile materials especially in sectors such as garments and outdoor gear where breathability matters most. It provides a practical and quick solution to evaluate how well fabrics let air pass through them influencing product design and performance.

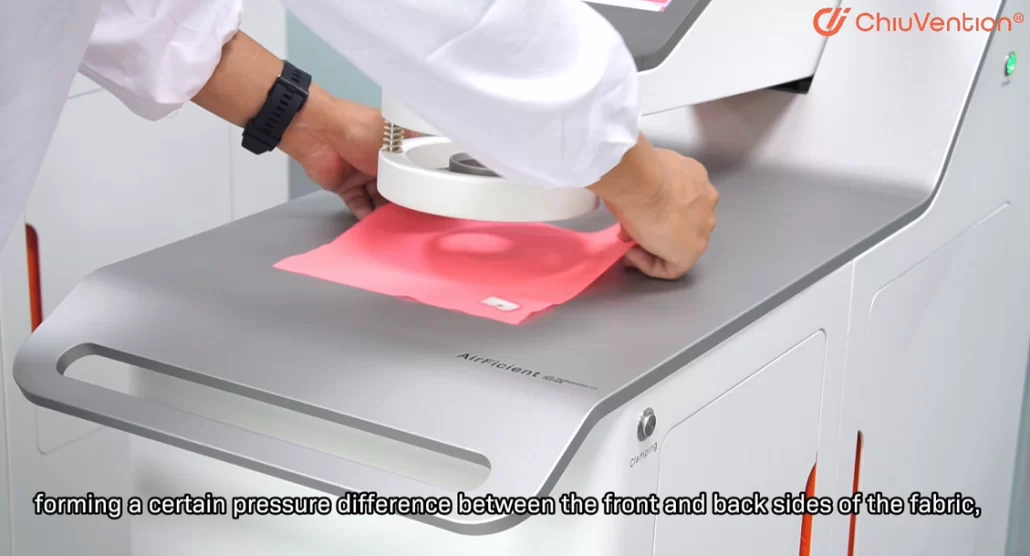

Want to know more about the Air Permeability Tester? Just click: AirFicient Air Permeability Tester

Which Kind Of Fabric Requires Air Permeability Test?

It is important to understand which materials are subject to air permeability testing, from clothes to industrial textiles to optimize comfort, performance, and functionality. Let’s look at some types of fabrics that derive benefits from air permeability testing and why it is significant.

Apparel Fabrics:

Air permeability tests are most frequently conducted on clothing materials. The texture of clothes contributes a lot in determining how much air can pass through them hence preventing overheating and moisture accumulation. Materials used for making clothing like cotton wool, and polyester among others have their air permeabilities tested to strike a balance between breathability and protection. If you’re dealing with a light summer dress or a heavy-duty outdoor jacket, checking the level of air penetration enables designers and manufacturers to make clothes that feel good when worn.

Technical Textiles:

Technical textiles include various specialized fabrics used in industries for functional purposes. In many cases, technical textiles need specific air-permeability properties such as transportation material for automotive airbags and filtration items among others just to meet the required performances. For instance, breathable membranes used in outdoor gear and sportswear should allow internal sweat vapor out while protecting the body from outside conditions.

Upholstery Fabrics:

For furniture and interior spaces upholstery fabrics, allowing breathing is crucial in making them comfortable and avoiding the accumulation of moisture. Upholstery velvet, linen, and microfiber are examples of fabrics that are used for upholstery. Therefore these fabrics go through a test to measure their air permeability which is how well they can allow air to move freely within them. Adequate air permeability not only improves comfort but also prevents the growth of molds and mildew thus increasing the lifespan of furniture as well as maintaining indoor air quality.

Medical and Hygiene Textiles:

Similarly, the medical settings rely on breathable textiles to keep the patients comfortable yet clean; hence it facilitates airflow so that skin irritation or infections may be avoided. To have an idea, hygiene products depend on breathable materials to manage moisture correctly and ensure that wearers enjoy comfortable products.

Air permeability testing benefits different types of fabrics across industries for optimum comfort, performance, and functionality. Whether clothing, technical materials medical applications, etc., knowing about the air permeability characteristics of textiles helps meet diverse needs among consumers or various sectors alike.

What Is The ASTM Method For Air Permeability Test?

The American Society for Testing and Materials (ASTM) has established standardized methods for conducting air permeability tests on fabrics, giving industry professionals guidelines for reliable and consistent testing procedures. The ASTM method of air permeability testing according to ASTM D737 is a systematic approach to evaluating the airflow properties of textiles. This article will discuss the ASTM method of air permeability testing and look at its key components in detail.

Background of the ASTM Method:

The aim of the ASTM method for air permeability testing is to create uniformity and accuracy in assessing fabric airflow characteristics. Textile professionals can obtain dependable information regarding air permeability by adhering to set rules that are critical in product development and quality assurance.

Benefits of the ASTM Method:

There are several advantages of utilizing the ASTM method for air permeability testing in the textile industry:

Standardization: This enables results across different laboratories as well as testing facilities to be comparable.

Reliability: By following instructions given by ASTM, textile experts have confidence when carrying out tests for air permeability that give accurate data regarding product development as well as quality control.

Compliance: It ensures compliance because regulatory bodies along with industrial standards organizations acknowledge the ASTM method.

An Introduction To Air Permeability Test Standard (ASTM D737):

ASTM is an acronym standing for the American Society for Testing and Materials (ASTM). One of their most effective and widely used standards is ASTM D737, which provides guidelines on how to perform air permeability tests on textiles. If you want to know all the details about ASTM D737, you can click Stand Test Methods for Textile Permeability ASTM D737-18

Significance of ASTM D737:

ASTM D737 acts as a yardstick for textile industries in terms of air permeability testing. This guideline offers an organized way of carrying out tests that enable textile professionals to acquire dependable outcomes that can be reproduced. By using these principles, manufacturing companies can have a standard evaluation of fabric’s aeration characteristics at all times thereby ensuring that their products are reliable.

Key Components of ASTM D737:

Scope and Application: The standard describes what fabrics to test and how. It makes clear which fabrics can be used for air permeability testing and the appropriate methodology to apply.

Sample Preparation: This outlines ways of preparing fabric samples before testing. Such may entail subjecting samples to prescribed temperature and humidity levels as a way of curbing deviations in test results.

Testing Apparatus: There are specific apparatus that must be available when carrying out air permeability tests according to ASTM D737. The principles of uniformity among different laboratories in terms of apparatus design and specifications have been ensured.

Test Procedure: Step-by-step guidance on how to perform an air permeability test is contained in the standard including sample positioning, pressure drops, airflow measurements, etc. These procedures are meant to ensure uniformity and accuracy during the execution of the tests.

What Is An Air Permeability Test Unit And How Many Kinds Of Permeability Test Units Are There?

This device is responsible for measuring how well a fabric allows air to pass through it. These units involve applying a pressure differential between the opposite faces of the test specimen which results in an airflow rate that is quantified in terms of volume per unit of time such as cubic feet per minute or liters per minute. Textile professionals rely heavily on air permeability tests due to their ability to accurately evaluate fabric breathability.

Types of Permeability Test Units:

Gurley Tester:

It measures how long it takes for a particular amount of air to go through a specific area of garment material while under constant pressure. The Gurley tester is specifically designed for testing products with low permeability like paper and non-woven fabrics.

Frazier Tester:

The Frazier tester is another highly used device in gauging air permeability. Unlike the Gurley tester which establishes airflow over a period, the Frazier tester measures the velocity of air through a fabric sample at a fixed pressure drop. This approach directly measures fabric permeability and is widely utilized in industries where the breathability of textiles is important such as clothing and outdoor apparel.

Shirley Air Permeability Tester:

The Shirley air permeability tester is an adaptable instrument for measuring a wide variety of fabrics including woven as well as non-woven materials. It applies a uniform difference in pressure across the test specimen while making use of precision instruments to measure the resultant flow rate. The air permeability tests by Shirley are flexible and accurate hence suitable for many applications in the textile industry.

Other Customized Test Units:

Apart from standard testing devices like Gurley, Frazier, and Shirley testers, textile experts may also consider other customized testing units designed specifically according to their preferences. These special units could have certain advanced options or changes that they must meet in some particular kinds of clothes or purposes.

What Is A Good Air Permeability Value?

Air permeability is the term used to refer to what extent a cloth allows air through it that can be measured in CFM or L/m²/s. Fabrics with higher values of air permeability allow more airflow, making them more breathable and comfortable for users.

Apparel Fabrics:

For apparel fabrics, the ideal air permeability value often falls within the range of 5 to 20 CFM (about 0.08-0.32 L/m²/s). Fabrics with air permeability values falling within this range have enough breathability and comfort; thus allowing sufficient airflow while maintaining durability and shape retention. On the other hand, fabrics used in activewear or summer clothing prefer high permeability levels closer to the upper limit of this range to boost moisture management and ventilation during physical activities or hot weather conditions.

Technical Textiles:

Air permeability needs vary depending on specific performance criteria such as protective clothing or filtration. For instance, in filtration applications, the air permeability of materials ranges from 20 to 200 CFM (about 0.32-3.2 L/m²/s) with the filtration efficiency and airflow resistance being considered while fabrics for protective garments have a target permeability rating below 5 CFM (around 0.08 L/m²/s) to prevent penetration by hazardous particles or chemicals but still allow breathability.

Upholstery Fabrics:

Breathable upholstery fabrics are essential in making furniture and interior spaces comfy also preventing moisture build-up. The optimal range for air permeability values of upholstery fabrics is typically between 5 and 50 CFM (i.e., around 0.08-0.80 L/m²/s), depending on factors like fabric composition, weave structure, and planned use. Upholstery applications that have higher rates of porosity enjoy good ventilation as well as moisture management leading to a long time of comfort and strength at the end of the day.

How Does The Air Permeability Of Fabric Affect The Comfort Of A Garment?

Here is how the comfort level of garments depends on the fabric’s air permeability.

Breathability and Ventilation:

Garments whose fabrics are more permeable to air allow for increased airflow. This improved air flow helps in removing body heat and moisture thus preventing overheating and discomfort, particularly during physical activities or warm surroundings. Breathable fabrics make clothes lighter to wear resulting in a cool and dry day.

Moisture Management:

Fabrics that allow movement of water vapor from the body reduce chances of sweating and buildup of moisture. Such moisture wicking keeps the skin dry as well as comfortable hence reducing chances of chaffing, irritation, or formation of odors. Clothes with good moisture management ability are highly recommended for people who exercise vigorously because they bring about lasting freshness and comfort.

Thermal Regulation:

The ability of air to pass through a fabric also contributes to temperature regulation by allowing extra heat to be lost and preventing cold wind from coming into the dress. Thus, fabrics that allow optimal levels of air permeability help to maintain a comfortable microclimate between cloth and skin which makes them warm even in cold conditions or cool during hot day times. This is thermal regulation which ensures that garments are always adaptable to changing environmental conditions, thus giving all year round comfort and flexibility.

How To Improve The Air Permeability Of Fabric?

Through particular techniques, such as using appropriate materials or applying advanced treatments, textile experts can achieve real improvements in breathability.

Material Selection:

It is vital to opt for fibers renowned for their ability to breathe. Natural fibers like cotton and linen have innate air permeability. It has been found that the air permeability of cotton fabric ranges between 3-25 cubic feet per minute (CFM). Additionally, linen fabrics have an elevated level of air permeability so they vary from 10-40 CFM [2]. Therefore, these materials should be chosen as a platform for improved breathability.

Fabric Structure Optimization:

Air permeability can be highly influenced by making adjustments to the fabric structure. This means that by increasing the openness of weave structures, such as using leno weave; air permeability can improve significantly. For example, one survey discovered that the use of leno weave increased air permeability in cotton fabrics from 4 to 12 CFM. Such structural improvements facilitate improved airflow and ventilation.

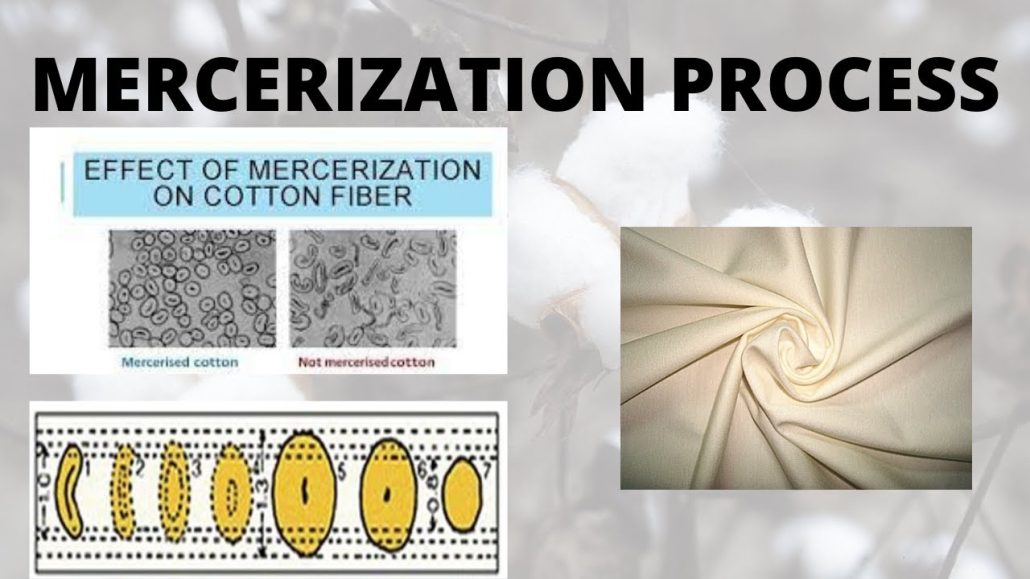

Surface Treatments and Finishes:

By altering surface properties, chemical treatments can enhance fabric breathability. Mercerization is a common treatment for cotton which strengthens fibers and makes them smoother so that airflow resistance is reduced. Mercillized cotton fabrics have been found to have air permeability values up to 30 CFM compared with those of untreated fabrics having values around 20 CFM Hence, surface treatments are very important in improving air permeability.

Mechanical Processes:

Brushing and, calendaring among other mechanical processes also increase fabric air permeability. Calendaring through compressing the layers reduces thickness and increases airflow. Calendered cotton fabrics based on studies showed different air permeability values ranging between 8- 18 CFMs as compared with uncalled ones equal to about 5CFMs.

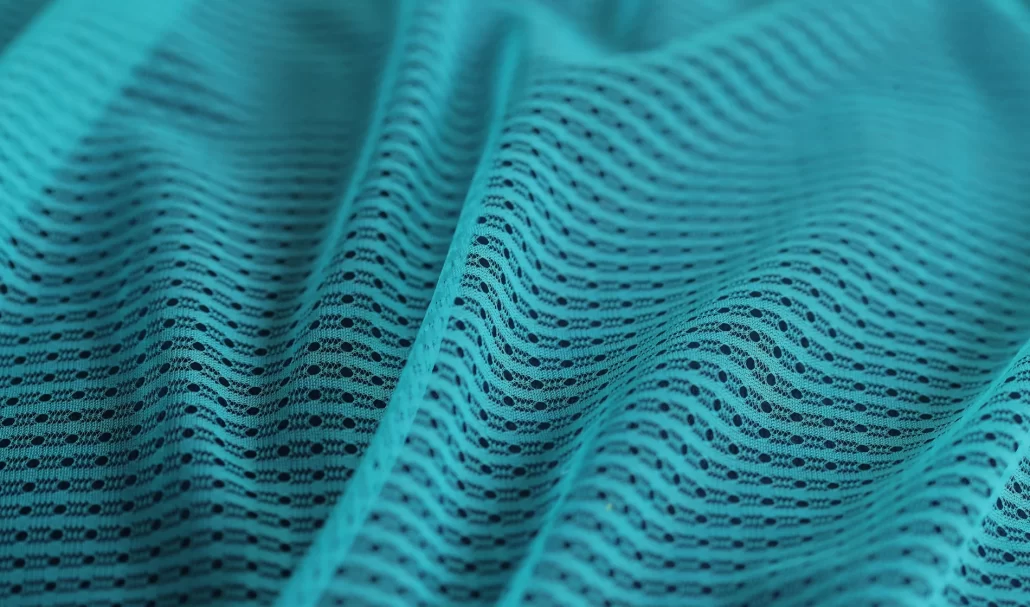

Fabric Design Innovations:

Innovative fabric designs, such as incorporating mesh panels or perforated sections, can optimize airflow. Research on garment design indicates that integrating mesh panels into activewear can increase air permeability by up to 50%, compared to standard designs.

Summing Up:

Improving fabric air permeability is essential for enhancing comfort and functionality in clothing and textiles. Air permeability tests, such as the Gurley and Frazier methods, guide product development across various industries, from apparel to medical applications. Standardized testing procedures outlined by the ASTM method ensure reliable results, while specialized test units like the Gurley and Frazier testers quantify fabric breathability accurately. By prioritizing breathability, textile professionals can create high-performance fabrics tailored to meet diverse consumer needs.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com