Garment Fusing Temperature Setting

Fusing, in fact, is the lamination of two or more textile surfaces by using thermoplastic resins. Therefore temperature is the most important (but also the most critical factor for the application of fusing.

What is Fusing Temperature?

In the day-to-day practice there is generally two kind of “temperature” mentioned:

In the day-to-day practice there is generally two kind of “temperature” mentioned:

- the temperature suggestion of the interlining supplier,

- the temperature setting or reading on the fusing machine.

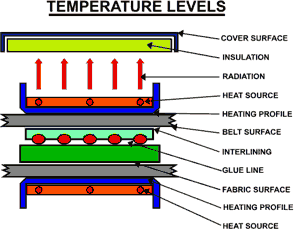

The fusing result is very much depending on the question whether or not the set values are indeed at exactly the points where they should be. A fusing machine has different temperature levels:

Remember:

To secure sufficient bond strength a certain minimum glue line temperature is needed, whereas for avoiding of fabric damages the surface temperature of the belts should be as low as possible.

This contradictory requirement must, by all means, be considered in the design of modern fusing equipment, particularly in view of the increasing number of delicate fabrics. For the proper selection of fusing machine settings it is important to know that the temperature development in the glue line depends very much on the weight of the fabric to be fused and that the temperature curve can vary drastically, as shown in the following graph:

Another important design condition: The system temperature, which is the temperature at the hottest spot on the actual electric heat source, should be as low as possible for the following reasons:/

Another important design condition: The system temperature, which is the temperature at the hottest spot on the actual electric heat source, should be as low as possible for the following reasons:/

- to avoid overheating of the material,

- to avoid belt damages when the power brakes down,

- to reduce energy cost,

- to minimize temperature radiation,

- to avoid cooling down times when switching off the machine,

- to avoid temperature variations.

The best heating system does not make sense when the temperature control system is poorly designed. Its functions must be fast and precise. At any time the temperature on the belt surface must correspond with the reading of the temperature regulator. There may not be any temperature swing, regardless of the degree of loading the machine with the material. A slow reacting control system leads to unacceptable temperature variations, whereas a fast reacting system keeps the fusing temperature on a constantly even level, as shown in the graph.

Slow temperature control systems require a setting at the lowest point, in order to avoid under fusing – with the disadvantage, however, that the unavoidable temperature peaks lead to overfusing, shrinkage, and resin strike back.

If primarily heavier fabrics are to be fused, or in case of sandwich or multi-layer fusing, higher heating capacity and a longer heating zone are needed to make sure that the machine capacity can follow the loading speed of the operators.

In this case heating form both top and bottom side with separate control is advisable to guarantee the correct temperature balance.

How to check temperature and heating of Fusing Machine?

- Most suitable for a temperature test are the well-known paper measuring tapes.

- The measured temperature between the belts (without fusing material) at medium machine speed should be in accordance with the temperature reading on the thermostat.

- In case of a separate digital temperature reading it should, after heating-up of the machine, indicate exactly the temperature setting.

- The easiest way to test the glue line temperature is also by using the paper tapes.

- To test the capacity and the reliability of a heating system one should prepare a number of swatches of heavier fabric and interlining with temperature tapes in-between, pass them through the machine successively and compare the results: All tapes should show the same temperature.

The heating capacity and the geometry of the heating zones are decisive for the application of a fusing machine in view of the material to be fused.

Lighter material like for shirts, blouses or dresses require generally lower heating capacity or shorter heating zones.

In this case, the main heat should come through the face fabric side, in order to have the melting resins flow towards the face fabric.

- Heating Profiles: with specially treated surface and optimum curvature for best belt contact

- Heating Mat: intimately laminated to the inside of the profile for best heat transfer

- Sensor Position: ideally next to heating mat and belt contact surface for quick reaction

- Contact Surface: continuous contact with the belts for continuous heat flow

- Profile Thickness: relatively thin for fast heat transfer to the belt surfaces

- Curved Heating Zones: for intensive contact between material and heating surface by high fusing belt tension

- Separate Heating Zones for optimum adjustment of the temperature balance according to fusing method.