Merchandising of Men’s Shirt in Bangladesh – A Case Study

A case study on Men's shirt manufacturing in a Garment factory in Bangladesh

More than 60% of the export share of Bangladesh is now contributed by ready-made garments. Due to the advent of containerization multimodal transport has created a new era in international trade.

Shirt Order Analysis In Mohammadi Group Ltd

Now, we will understand the complete order analysis and costing process involved in manufacturing an H&M Shirt.

Design studio

The first step is always done by the design studio when the collection type was fixed along with the meeting date in Spain. The designers first sat on a meeting internally by teams to decide their styles. So, while a team had prepared bottom items others had prepared tops items. It is a shirt that can be classified into a group of Tops. This Tops section team is led by Nibedita Bhabani where the other two designers are included also. In the case of preparing this Shirt, designer Nurjahan Akter made the primary design.

For a limited time span, they sorted out some old patterns of their collections where they got a style of a similar product named “Emilda”. So, they found out the pattern and the measurement of it. They prepared the shirt similar to the original design sent by the buyer named “Emily”.

Two seasons are generally counted in the fashion industry which are Summer/ Spring (SS) and Autumn/Winter (AW). So, the picture of samples they got from the buyer side was a Shirt for the summer season and the month was currently going on February. So, the Shirt was about to be confirmed for this summer season in 2013.

The design studio made the dress with a very light, soft georgette fabric. According to the measurements, they sewed the shirt with 1 pocket on the right panel. They have used here random bleach wash which is a heavy wash for giving the cloths whiter look and they sent it with their meeting team in mid-February.

Product Pack

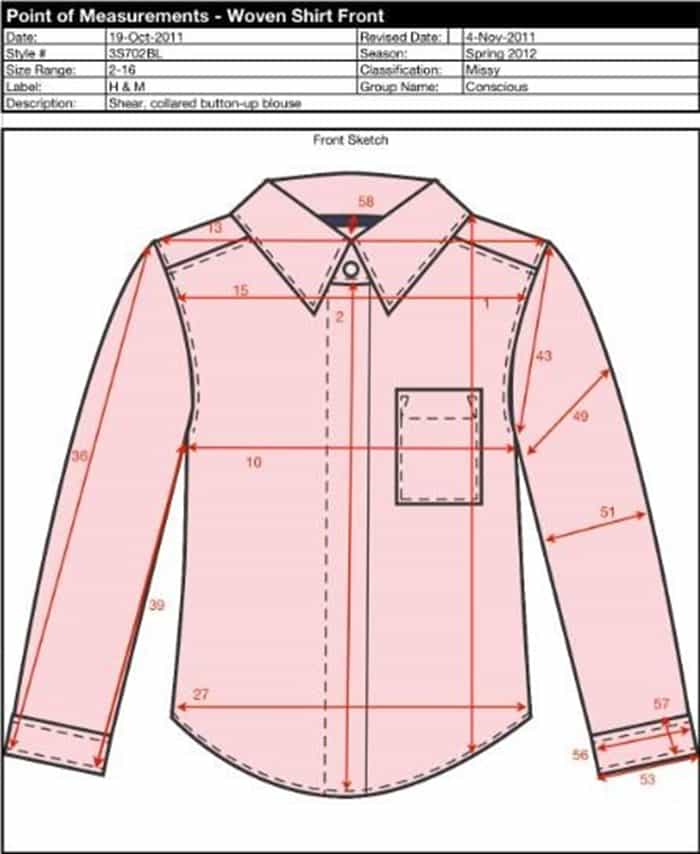

The product pack is the first detail of the product that comes from the buyer. This product pack is contained with fabric type, order process, their description of interest, trims description, wash description, and measurements. The pack also contains amendments if the supplier sent any samples before. Overall, it is the reflection of buyers’ wants and demands.

Many requirements are also described here to fulfill. The product pack has three parts – the first part contains the mail and official order for making samples of a particular style with their different instructions of fabric wash and fit comments. The second part is attached with the picture of the style with important instructions suppliers need to follow, here also the trims instruction and reference are given. The third part contains the measurement sheet. It consists of the measurements that the supplier needs to maintain according to their size chart. After the meeting in Spain, the design of Emilda had been given by H&M for reference and with some changes, they sent the product pack on February 18, 2013, to place an order for Emily.

Here, with the pattern file, they sent the mail with all the requirements and instructions. Here, at first, the client part changed the name of Emily to Harriet. They wanted to have their reference by the name of Harriet. Second, they sent here their desired fabric, which has the code GPP 1455. Actually, this fabric was not used by the Mohammadi Group Ltd design team rather they used the fabric with the code GPP 1311. The reason for changing the fabric can be the color of the finished product that Mohammadi sent.

The sample sent by Mohammadi had a bit yellowish look after wash which was not demanded by H&M. They wanted a clear look at the product. They also instructed about the wash of the garment. Trims were also instructed. The buyer sent Mohammadi their original trims or, buttons, the fusing. Thread is also mentioned there. They wanted to use the same thread for sewing as a sample sent in Spain.

At last, they instructed about the style of the product they wanted to see. They selected the pattern and the style of the supplier but they have changed it in various portions according to their demand. They had different thoughts about the fit of the product. Fit means style and outlook of product which is mostly related to the measurement of the garment. They sketched the placement of buttons, cutting of collar shapes, yoke panel style, and canceled the darts at the back which refers to a sewing style. So, they shared the following Tech Pack of the Harriet Shirt

First Fit

After sending the first fit Mohammadi got their reply from the buyer. As Mohammadi was confirmed about the order from the meeting, they did the changes according to the buyer by the first week of March. In the product pack, the buyer changed the measurements so they needed to follow the new pattern sent by the buyer. This pattern file is a special artwork file uploaded by the buyer with which the pattern team works. This pattern rectification is mandatory for all the styles Mohammadi supplies to the customer. This pattern is also used to measure the cost of the garment for knowing the consumption of the fabric for the product.

After completing the pattern rectification, the garment goes for sewing. Here, the design studio directly does not develop any changes of the style, according to the buyer’s requirements; the development team of the marketing department arranges this. For the style Harriet, they wanted to change the fabric. And remade it as they wanted without the twist, pockets in front, and their suggested button placement. So, with these, all corrections Mohammadi sent the first sample for fit and got the comment after one week they sent it. Now, the fabric was approved but in the case of measurement, the approval was not ok for the garment.

At the first product pack, they included the sleeve but at the time of comment, they did not like that and wanted to add another hanger neck inside. There was another style CAMI Lace Dress was also going on parallel and H&M used things from there as a reference of Harriet. The buyer wanted to change the thread as well with the after wash look as they wanted it pure white. The garment looked yellowish after wash which was not preferred by H&M.

Second Fit

After these all comments the responsibility of merchandisers was to get all the trim sources and arrange all the requirements H&M wanted. So, they tried to source all these and according to that, they sent their second fits in the last week of March ‘13. After that, they have got a comment from the H&M local office about the fit. According to the fit’s comments, the fabric is ok as the approved one. Thread is ok in this case with what they were not satisfied with before.

The main problem Mohammadi again faced is the measurement which is fluctuating with the original reference. The buyer sent a measurement of 15 cm. So, they needed to send the same style again. The fabric was used by the team of Mohammadi was 15 cm in length after sewing but just after the wash, it got shrunk. Firstly, it has been arranged locally for minimizing the cost but then the fabric does not work the right way so they need to change it and for the further procedure they used the imported fabric. The fabric used in the placket of Harriet is appreciated by the buyer and during the unavailability of the prior fabric they have ignored it for piping but the buyer wanted the same fabric they used at the time of collection.

The Wash of the fabric is adjusted in this sample, but the buyer wanted Mohammadi to follow the leg mock sent prior to getting approval. But the main problem of adjusting fabric is there and as this is the confirmed order buyer requested them to send an urgent size set as the delivery date was very near. So, it was decided to source the fabric from China.

Size set sample

As the order is confirmed and after the second fit sample the supplier Mohammadi sent the size set to the buyer and then the fabric problem is requested to ignore. This time the wash is sent as the buyer wanted that the light bleach wash which creates an ‘Ecru’ color of georgette and the wrong measurement has also been corrected.

In case of size set if different color remains then jumping sizes are provided by the suppliers like fixing the Medium size other colors are sent one-pieces for one sample. So, before of size set only the Medium size sample has been manufactured but for the size set samples of all the sizes of the size chart are needed. So, the pattern is made in a new way for different sizes. It requires grading. At that time, the calculation of different sizes varies, and a mismatch of measurement can be occurred for doing the grading. The problem occurs here for the change of Fabric roll also. Depending on the characteristics of fabric it sometimes got shrunk and sometimes stretched.

Here, in the case of Harriet, there are no different color shades and wash instructions available. So, just follow the size chart of H&M, Mohammadi sent the size set to the buyer. Here, the responsibility of the Development team is over now, the production team will take the workflow and further procedures for sending Harriet to Spain will be done by the Production team.

Production process

The first part of the production process is sending the PP sample which refers to Pre Production sample where all actual trims, fabric, and wash standard is followed. Generally in case of different colors sample of all sizes with all colors are sent but in case of Harriet, there is just one color so, the sample is sent off four pieces of different sizes. Like, the Small (S), Medium (M), Large (L), Extra Large (XL) are sent to the buyer as sample size. All samples go through the local office of H&M so, eight samples were sent as pre-production samples (PP samples) for style Harriet.

The thesis is a brief about ‘Study of business strategy in a Bangladeshi knit garments buying. Exports of textiles, clothing, and ready-made garments (RMG) accounted for 77% of Bangladesh’s total merchandise exports in 2002. https://www.bdwear.com/

Can you suggest new and proven advanced machineries to making shirt and pants

Great post, I believe website owners should learn a lot from this site it’s really user friendly. So much superb info on here.

https://www.facebook.com/PSGLending/