Sewing Needles

This comprehensive guide should provide readers with a deep understanding of sewing needles, from their historical significance to practical usage tips. Whether you’re a beginner or an experienced seamstress, the right knowledge about sewing needles can elevate your sewing projects and help you achieve professional results.

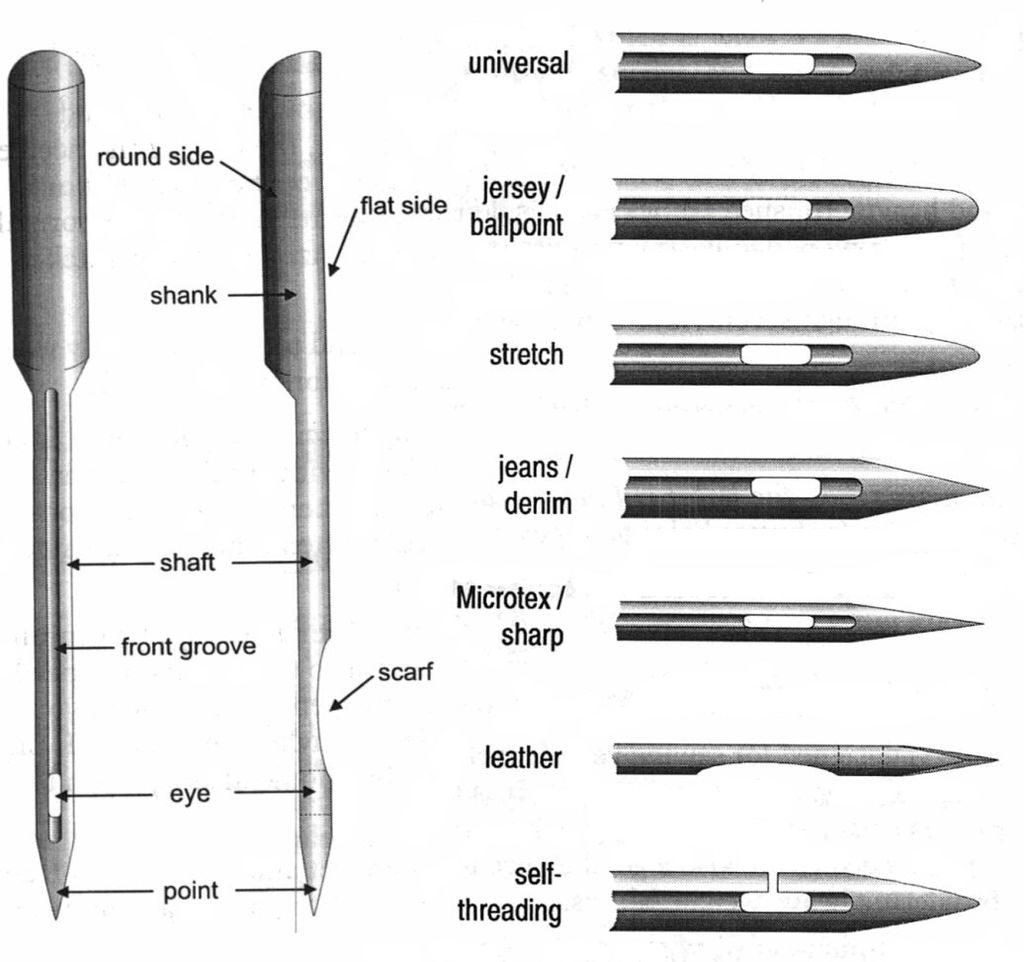

A sewing needle is a long slender tool with a pointed tip. The needle must be able to penetrate the material being sewn, by pushing the yarns aside according to the application, without damaging it. The various parts of the needle are: The shank, The shoulder, The blade, Long Groove, Short Groove, The eye, The point and the Tip.

Sewing needles have played a pivotal role in the history of human craftsmanship and continue to be essential tools in the world of sewing and textile arts. From their humble beginnings as crude bone implements to the precision-engineered needles of today, they have evolved to meet the demands of various fabrics and sewing techniques.

Understanding the anatomy of sewing needles, including their parts and sizes, is essential for selecting the right needle for your sewing projects. Whether you’re working with delicate silks, heavy denims, or stretchy knits, choosing the correct needle can significantly impact your stitching quality and overall sewing experience.

Caring for your sewing needles is equally important, as proper maintenance ensures their longevity and performance. Regularly replacing dull or damaged needles, cleaning your sewing machine, and using quality thread all contribute to smoother sewing outcomes.

Troubleshooting common needle-related issues and practicing needle safety and best practices are essential for safe and enjoyable sewing experiences. Whether you’re a beginner or an experienced seamstress, these guidelines help you avoid accidents, improve stitch quality, and make your sewing projects more successful.

In the world of sewing, needles are not just tools; they are the conduits through which creativity and craftsmanship flow. By understanding, selecting, caring for, and safely using sewing needles, you can unlock your full potential as a sewist and continue to create beautiful and functional textile works of art.

Sewing Needle

A sewing needle is a long slender tool with a pointed tip. The needle must be able to penetrate the material being sewn, by pushing the yarns aside according to the application, without damaging it. Modern needles are manufactured from high carbon steel wire, nickel or gold plated for corrosion resistance.

Needle Points

Needles are manufactured with a wide variety of needle points appropriate for the different properties of materials which have to be sewn. The needlepoint can be located either centrally or eccentrically. There are two basic classes of points:

- Round points

- Cutting points

Slim Set Point Needles – can penetrate the yarns of the material being sewn through its sharp point and is ideal for all woven fabrics because it helps to produce an even stitch and causes a minimum of fabric puckering. They are used for Blind stitches and for fine, densely woven fabrics. These points are not suitable for knitted fabrics.

Set Cloth Point – needles are slightly rounded to displace yarns of the material being sewn without damaging them. This is most commonly used point.

Heavy Set Point – needles are strongly blunted. These are used for button sewing machines.

Ball Points – Light Ball Point is used for sensitive fabrics such as knits, to prevent damage to the loops. This is crucial for maintaining the fabric’s elasticity. Medium ballpoint and heavy ballpoint are used for fabrics containing stretchable yarns. While sewing the threads are displaced not pierced. The needle pushes between the fabric yarns rather than “cutting rough” the yards.

Cutting Points – are used for sewing leather, coated or laminated fabrics. These are classified and named according to the position of the cutting edge and its shape. The shapes are named with regard to the form of the cutting edge for example spear point, triangular point, diamond point etc. The shape of this needle will create a slit (rather than a large hole) through which the thread will pass.

Needle sizes

Suitable sewing needle type is one of the most important parameters for ensuring the effective and fault free sewing process it will depend on the characteristics of the needle type, needle point, needle fineness, fabric material, the size of sewing thread, the seam type and stitch type.

It is important to use correct needle size for the type of fabric being used. The metric size “Nm” of a needle defines the diameter of the blade (in 1/100 mm) at a point just above the scarf. Fine needles are around Nm 70, medium needles abound Nm80-Nm90 while thicker needles are around Nm100.

The convention for sizing is that the length and thickness of a needle increase as the size number decreases. Delicate fabrics such as silk, chiffon, voile, fine lace and organdie would need a fine “size 9” needle. Lightweight fabrics such as synthetic sheers, taffeta, velvet, stretch fabric and tricot would need a “size 11” needle.

Medium weight fabrics such as poplin, linen, chambray, wool crepe, flannel, knits, jersey, wool, and satin would need an S “size 14” needle. Medium-heavy weight fabrics such as sailcloth, gabardine and tweed fabrics would need a “size 14-16” needle.

Heavy fabrics such as denim, upholstery and canvas fabrics would need a “size 16-18” needle. Most readily available machine needles are sized from 9 to 18. The smaller the number, finer the needle.

Needle Anatomy: Understanding of the Parts

Understanding the anatomy of a sewing needle is essential for selecting the right needle for your sewing project and ensuring that it functions properly with your sewing machine. Here are the key parts of a sewing needle:

- Shank:

- The shank is the upper part of the needle, which is inserted into the sewing machine. It is cylindrical in shape and fits into the needle holder or clamp on the sewing machine.

- Shaft:

- The shaft is the long, slender portion of the needle that extends below the shank. The shaft’s diameter varies depending on the needle type and size, with thicker shafts for heavy-duty needles and thinner ones for lightweight needles.

- Groove:

- The groove is a shallow indentation or channel on one side of the shaft. It runs along the length of the shaft and helps guide the thread as it enters the eye of the needle. The groove ensures that the thread stays in the correct position while sewing.

- Eye:

- The eye of the needle is the small, open hole at the bottom of the shaft. It is where the thread passes through to be carried down into the fabric. The size and shape of the eye vary based on the needle type and size. Larger eyes are used for thicker threads.

- Point:

- The point of the needle is the very tip that pierces the fabric. The shape of the point varies depending on the needle type. For example, ballpoint needles have a rounded point, while sharp needles have a fine, pointed tip.

- Scarf:

- The scarf is a flattened area on the backside of the needle, just above the eye. It creates space for the bobbin hook to pass by the needle as it forms stitches. The size and shape of the scarf vary depending on the sewing machine’s design and the needle’s purpose.

- Shoulder:

- The shoulder is the area where the shaft meets the shank. It is an important reference point for positioning the needle correctly in the sewing machine. Different sewing machines may have specific instructions for aligning the needle with the shoulder.

- Needle Type and Size Markings:

- Sewing needles are typically marked with information about their type and size. This information can include the needle type (e.g., Universal, Jeans, Embroidery) and the needle size, which is usually denoted by a number. Smaller numbers indicate thinner needles, while larger numbers represent thicker needles.

- Needle Brand and Identification:

- Some needles also bear the manufacturer’s brand or logo and may have additional identification markings. These markings help you identify the needle’s brand and model.

It’s crucial to choose the right needle for your sewing project, as using the wrong type or size can lead to issues like skipped stitches, fabric damage, or thread breakage. Consult your sewing machine’s manual and consider the fabric and thread you plan to use to select the appropriate needle. Proper needle maintenance, including changing the needle regularly, is also important for achieving optimal sewing results.

History of Sewing Needles

The history of sewing needles is a fascinating journey that spans thousands of years, reflecting the evolution of human ingenuity and craftsmanship. Here’s a brief overview of the history of sewing needles:

- Early Needles: The earliest evidence of needles used for sewing dates back to the Paleolithic era, around 25,000 years ago. These early needles were typically made from materials such as bone, ivory, or antler and were relatively large and crude compared to modern needles.

- Metal Needles: The transition from organic materials to metal needles marked a significant advancement. Around 2000 BCE, people began crafting needles from copper, bronze, and iron. These metal needles were smaller, more durable, and allowed for finer, more intricate sewing.

- Ancient Civilizations: In ancient civilizations like Egypt, Greece, and Rome, needles played a crucial role in textile production and clothing construction. These needles were often made of bronze or iron and were used for sewing garments, sails, and other fabric-related tasks.

- Middle Ages and Renaissance: During the Middle Ages and Renaissance, needles became more specialized, with some designed for embroidery and others for general sewing. The craft of needle-making itself saw significant advancements, leading to finer and more precise needles.

- Industrial Revolution: The Industrial Revolution in the late 18th and early 19th centuries brought about significant changes in needle production. Mass production techniques allowed for the creation of consistent, high-quality needles on a large scale.

- Needle Manufacturing: By the mid-19th century, sewing needles were manufactured using machinery, greatly increasing their availability and affordability. Innovations in needle manufacturing led to the development of various needle types, including hand-sewing needles, knitting needles, and machine needles.

- Specialized Needles: As technology advanced and different sewing techniques emerged, specialized needles were created to meet specific needs. For example, the introduction of the sewing machine in the 19th century led to the development of sewing machine needles with unique shapes and sizes.

- Modern Needles: Today, sewing needles come in a wide variety of materials, sizes, and types to suit different sewing projects. Needles are made from materials like stainless steel, nickel-plated steel, and even titanium. They are designed for sewing by hand, embroidery, quilting, and use with various sewing machines.

- Future Developments: Needle technology continues to evolve, with ongoing research into innovative materials and designs. The goal is to create needles that are more efficient, durable, and capable of handling increasingly complex fabrics and sewing tasks.

In summary, the history of sewing needles is a testament to human innovation and the desire to create tools that make the art of sewing more efficient and accessible. From primitive bone needles to the highly specialized needles of today, the evolution of sewing needles reflects the evolution of human textile and garment-making techniques.

Types of Sewing Needles

There are numerous types of sewing needles available, each designed for specific purposes and fabrics. Choosing the right needle for your sewing project is crucial for achieving the best results. Here are some common types of sewing needles:

- Universal Needles:

- These are the most common type of needles and are suitable for general-purpose sewing. They work well with woven and knit fabrics.

- Ballpoint Needles:

- Ballpoint needles have a rounded tip and are designed for use with knit fabrics like jersey and interlock. They prevent snags or damage to the fabric by pushing aside the fibers rather than piercing them.

- Sharp Needles:

- Also known as Microtex or Quilting needles, these needles have a very fine, sharp point, making them ideal for precision sewing, quilting, and working with lightweight, tightly woven fabrics like silk and microfiber.

- Jeans/Denim Needles:

- These needles have a strong, thick shaft and a sharp point designed for sewing through heavy fabrics like denim, canvas, and upholstery materials.

- Leather Needles:

- Leather needles have a wedge-shaped point that easily penetrates leather, suede, and other thick, non-woven materials. They’re also useful for vinyl and faux leather.

- Embroidery Needles:

- These needles have a larger eye to accommodate embroidery threads and are often used for decorative stitching and embroidery on various fabrics.

- Twin Needles:

- Twin needles have two needles attached to a single shaft, spaced apart. They are used for creating parallel rows of stitching, ideal for hems and decorative effects.

- Stretch Needles:

- Designed for stretchy or elastic fabrics, these needles have a special construction to prevent skipped stitches and fabric damage when sewing on materials like Lycra, spandex, and knits.

- Topstitching Needles:

- Topstitching needles have an extra-large eye and a deeper groove to accommodate thicker topstitching threads. They are used for decorative topstitching on garments and accessories.

- Quilting Needles:

- Quilting needles have a tapered point and are specifically designed for machine quilting. They help with piercing through multiple layers of fabric and batting.

- Wing Needles:

- Wing needles have wide, flat “wings” on the sides of the needle, which create holes in the fabric for decorative heirloom-style stitching, often used in embroidery and delicate fabrics.

- Serger Needles:

- Serger or overlock machine needles are specially designed for sergers or overlock machines, which use multiple threads to create finished seams. They come in various types, including standard, ballpoint, and specialty serger needles.

- Self-Threading Needles:

- These needles have a built-in mechanism that makes threading easier, especially for those with visual impairments or fine motor skill difficulties.

- Specialty Needles:

- Depending on your sewing needs, you may also find specialty needles for specific tasks like beading, darning, or even quilting with metallic threads.

Always consult your sewing machine’s manual and consider the fabric you’re working with to choose the appropriate needle type and size for your project. Using the right needle can significantly improve the quality and ease of your sewing.

Needle Sizes: What Do the Numbers Mean?

- Needle Size (or Thickness):

- The first number on a sewing needle represents its size or thickness. It is usually a two-digit number, such as 80, 90, 100, etc. The size number indicates the diameter of the needle shaft in hundredths of a millimeter or thousandths of an inch, depending on the measurement system used.

- Smaller size numbers indicate thinner needles, while larger size numbers represent thicker needles. For example, a size 80 needle is thinner than a size 100 needle.

- The appropriate needle size depends on the type of fabric and thread you plan to use. Lightweight fabrics like chiffon or silk may require a smaller needle (e.g., size 60 or 70), while heavy fabrics like denim or canvas may require a larger needle (e.g., size 110 or 120).

- Needle Type (or Purpose):

- The second number on a sewing needle indicates its type or purpose. This number is often found after a forward slash following the size number. For example, a needle labeled “80/12” indicates a size 80 needle with a type 12.

- Different needle types are designed for specific sewing tasks and fabric types. Common needle types include Universal, Ballpoint, Sharp, Jeans, Embroidery, Quilting, and more. The type of needle you choose depends on the fabric and sewing technique you plan to use.

For example:

- A “70/10” needle is relatively small and fine, suitable for lightweight fabrics like silk or chiffon.

- An “80/12” Universal needle is a general-purpose needle for medium-weight woven and knit fabrics.

- A “90/14” Jeans needle is designed for heavy denim and canvas fabrics.

When selecting a needle, consider both the size and type to ensure that it is appropriate for your specific sewing project. Using the right needle size and type can improve stitch quality, prevent fabric damage, and make your sewing experience more enjoyable. Always consult your sewing machine’s manual for recommendations on needle size and type for different fabrics and techniques.

Selecting the Right Needle for Your Project

- Consider the Fabric:

- Start by examining the fabric you plan to sew. Is it lightweight or heavyweight? Is it a woven or knit fabric? The type and weight of the fabric play a significant role in selecting the right needle.

- Determine the Fabric Type:

- For lightweight, delicate fabrics like silk, chiffon, and organza, choose a fine needle with a smaller size number (e.g., 60/8 or 70/10).

- For medium-weight woven fabrics like cotton or linen, a Universal needle (e.g., 80/12) is often a suitable choice.

- For heavyweight fabrics such as denim, canvas, or upholstery materials, opt for a larger, stronger needle (e.g., 100/16 or 110/18).

- Consider the Needle Type:

- Different needle types are designed for specific purposes. Here are some common needle types and their uses:

- Universal Needle: Suitable for general sewing on a variety of fabrics.

- Ballpoint Needle: Designed for knit fabrics to prevent snags.

- Jeans/Denim Needle: Ideal for heavy, dense fabrics like denim.

- Sharp/Microtex Needle: For precise stitching on lightweight fabrics.

- Embroidery Needle: Used for embroidery work with specialty threads.

- Quilting Needle: Designed for machine quilting projects.

- Leather Needle: Appropriate for leather, suede, and non-woven materials.

- Choose the needle type that best matches your project’s requirements.

- Different needle types are designed for specific purposes. Here are some common needle types and their uses:

- Consider Thread Type:

- The type and thickness of the thread you plan to use should also influence your needle choice. Heavy threads may require a larger needle with a larger eye.

- Check Your Sewing Machine Manual:

- Consult your sewing machine’s manual for guidance on needle selection. The manual often provides recommendations based on the machine’s capabilities and the type of stitches it can create.

- Test Stitch on a Scrap Piece:

- If you’re unsure about the needle size or type, it’s a good idea to test a few stitches on a scrap piece of fabric before starting your project. This allows you to assess stitch quality and make any necessary adjustments.

- Replace Needles Regularly:

- Sewing needles can become dull over time, leading to poor stitch quality and potential fabric damage. Replace your needle after every 6-8 hours of sewing, or if you notice any issues with your stitches.

- Keep a Needle Reference Chart:

- Maintaining a needle reference chart in your sewing area can be helpful. This chart can list various needle types and their recommended uses, making it easier to select the right needle quickly.

Remember that selecting the correct needle is essential for achieving the best sewing results. Taking the time to choose the appropriate needle based on fabric type, needle size, and needle type can make your sewing projects more enjoyable and successful.

Caring for Your Sewing Needles

- Use the Right Needle for the Job:

- Always select the appropriate needle type and size for your sewing project. Using the wrong needle can cause issues like fabric damage, skipped stitches, or thread breakage.

- Replace Needles Regularly:

- Sewing needles can become dull over time, especially when sewing through heavy fabrics or using them for an extended period. Replace your sewing needle after every 6-8 hours of sewing or when you notice a decline in stitch quality.

- Inspect Needles Before Use:

- Before inserting a new needle or reusing a needle, inspect it for any signs of damage or bending. Bent or damaged needles can cause sewing issues and should be discarded.

- Install Needles Properly:

- Ensure that you insert the needle correctly into your sewing machine. Refer to your machine’s manual for guidance on how to do this. Misaligned needles can lead to sewing problems.

- Thread the Needle Carefully:

- When threading your needle, avoid pulling the thread through forcefully, as this can cause burrs or nicks in the eye of the needle. Instead, trim the thread end cleanly and use a needle threader if necessary.

- Clean Your Machine Regularly:

- Dust, lint, and fabric particles can accumulate in your sewing machine, leading to needle and stitching issues. Clean your machine’s needle area and feed dogs regularly, following the manufacturer’s instructions.

- Use Quality Thread:

- Cheap or low-quality thread can leave residue on your needle, affecting its performance. Invest in good-quality thread to reduce the buildup of residue.

- Protect Needles During Storage:

- When storing sewing needles, use a needle case or a piece of foam to protect the needle tips. This prevents accidental damage and keeps the needles in good condition.

- Needle Sharpeners:

- Some sewing enthusiasts use needle sharpeners to extend the life of their needles. These tools can help reshape and sharpen the point of a dull needle. Follow the manufacturer’s instructions when using a needle sharpener.

- Dispose of Needles Properly:

- When discarding used needles, be sure to do so safely. Consider using a needle disposal container designed for sharps or needles to prevent injury to others.

- Keep a Needle Log:

- If you have various types and sizes of needles, maintain a needle log or chart that helps you keep track of which needles you’ve used and when they were last replaced. This can be particularly helpful if you work on multiple projects simultaneously.

- Be Gentle with Your Machine:

- Avoid sewing over pins or forcing your fabric through the machine, as these actions can cause needles to bend or break.

By following these tips for caring for your sewing needles, you can ensure that your needles remain in good condition, resulting in smoother and more successful sewing projects.

Troubleshooting Needle Issues

- Skipped Stitches:

- If your machine is skipping stitches or creating uneven stitches, the needle may be dull or bent. Replace the needle with a new one of the correct type and size for your fabric.

- Fabric Puckering:

- Puckering occurs when the fabric gathers or wrinkles unintentionally while sewing. This can happen if the needle is too large or too small for the fabric. Ensure that you’re using the appropriate needle size for your fabric type.

- Thread Breakage:

- Thread breakage can occur due to various reasons, including using a damaged or incorrect needle, using old or low-quality thread, or incorrect threading. Try the following:

- Replace the needle with a new one of the correct type and size.

- Ensure you’re using good-quality thread suitable for your fabric.

- Re-thread your machine following the proper threading path.

- Thread breakage can occur due to various reasons, including using a damaged or incorrect needle, using old or low-quality thread, or incorrect threading. Try the following:

- Fabric Jamming or Breaking:

- If the needle jams in the fabric or causes the fabric to tear, it could be due to a few factors:

- The needle may be too large or too dull for the fabric. Use the appropriate needle size and type.

- Ensure the fabric is properly fed through the machine and isn’t getting caught on rough edges or feed dogs.

- If the needle jams in the fabric or causes the fabric to tear, it could be due to a few factors:

- Thread Nesting (Thread Bunching Underneath):

- Thread nesting under the fabric is often caused by issues with the bobbin, tension, or incorrect threading. Try the following:

- Re-thread the upper thread, ensuring it’s properly seated in the tension discs.

- Check the bobbin and bobbin case for any loose threads or debris.

- Adjust the upper thread tension as needed.

- Thread nesting under the fabric is often caused by issues with the bobbin, tension, or incorrect threading. Try the following:

- Breaking Needles:

- If needles are breaking frequently, it may be due to one or more of the following:

- Using a needle that’s too thin for the fabric or too thick for the thread.

- Sewing over pins or other hard objects.

- An issue with the machine’s timing, which may require professional servicing.

- If needles are breaking frequently, it may be due to one or more of the following:

- Uneven Feed or Fabric Not Advancing Properly:

- If the fabric isn’t feeding evenly, it may be because the needle plate or feed dogs are dirty. Clean them according to your machine’s instructions.

- Ensure the presser foot is down and properly engaged.

- Needle Hits the Presser Foot:

- If the needle hits the presser foot or needle plate, make sure you’re using the correct needle type and size for your project. Adjust the needle position if your machine allows it.

- Needle Threader Malfunctions:

- If your sewing machine has an automatic needle threader and it’s not working correctly, refer to your machine’s manual for troubleshooting steps or contact the manufacturer’s customer support.

- Needle Won’t Stay in Place:

- If the needle keeps coming loose or falling out, ensure it’s properly inserted and tightened in the needle clamp.

If you’ve tried troubleshooting these issues and still encounter problems, it may be necessary to consult your sewing machine’s manual or seek assistance from a professional sewing machine technician. Regular maintenance and using the correct needles for your projects can help prevent many needle-related issues.

Sewing Needle Brands and Recommendations

There are several reputable sewing needle brands that produce high-quality needles for various sewing needs. While the choice of a needle brand often comes down to personal preference and availability, here are some well-known sewing needle brands and their popular needle lines:

- Schmetz:

- Schmetz is one of the most recognized and widely used needle brands worldwide. They offer a wide range of needle types and sizes, making it easy to find the right needle for your sewing project.

- Popular Schmetz needle lines include Universal, Microtex (Sharp), Ballpoint, Jeans/Denim, and Embroidery needles.

- Organ Needle Co.:

- Organ is another well-respected needle brand known for producing high-quality sewing needles.

- Their needles are used in many sewing machines and sergers, and they offer various needle types like Universal, Ballpoint, and Leather needles.

- Singer:

- Singer, a famous sewing machine manufacturer, also produces sewing needles.

- Singer needles are readily available and suitable for general sewing tasks. They offer Universal, Ballpoint, and Heavy Duty needles, among others.

- Klasse:

- Klasse is known for its range of quality needles that cater to different sewing needs.

- Their needle lines include Universal, Ballpoint, Jeans, and Stretch needles.

- Dritz:

- Dritz is a brand that offers a variety of sewing notions and accessories, including sewing needles.

- Their needles are suitable for general sewing, quilting, and embroidery.

- Prym:

- Prym is a European brand known for its sewing and craft products, including sewing needles.

- They offer a range of needle types, including Universal, Ballpoint, and Quilting needles.

- Inspira by Husqvarna Viking:

- Inspira is a needle brand associated with Husqvarna Viking sewing machines.

- Their needles are designed to work seamlessly with Husqvarna Viking machines and cater to various sewing needs.

When selecting sewing needles, it’s essential to consider the type of fabric you’ll be sewing, the thread you’ll use, and the specific requirements of your project. Always refer to your sewing machine’s manual for recommendations on compatible needle brands and types, as some machines may perform better with certain needle brands.

It’s also worth noting that premium sewing needles can make a difference in stitch quality and overall sewing experience. Experiment with different needle brands and types to find the ones that work best for your needs and preferences.

Needle Safety and Best Practices

Needle safety and best practices are crucial to ensure safe and enjoyable sewing experiences. Sewing needles can be sharp and pose a risk of injury if not handled properly. Here are some essential safety tips and best practices when working with sewing needles:

- Use Needle Guards or Caps:

- When not in use, cover the needle with a needle guard or cap. This prevents accidental pricks and protects the needle from damage.

- Handle Needles Carefully:

- Always handle sewing needles with care. Avoid touching the sharp point, and never place your fingers in front of the needle while the machine is running.

- Replace Dull or Damaged Needles:

- Dull or damaged needles can cause sewing problems and pose safety risks. Replace needles regularly, especially if they become bent or show signs of wear.

- Dispose of Used Needles Safely:

- When disposing of used needles, place them in a designated needle disposal container or a sharps container. Do not throw needles directly into the trash, as they can pose a risk to waste handlers.

- Keep a Magnet Handy:

- A magnet can be useful for picking up and safely storing dropped needles or pins. Magnetic pin cushions are also handy for this purpose.

- Stay Focused and Avoid Distractions:

- Sewing requires concentration. Avoid distractions, such as using your phone or watching TV, while sewing to minimize the risk of accidental needle pricks or mistakes.

- Thread Needles Carefully:

- When threading a needle, take your time to avoid accidentally poking your fingers. If you have difficulty threading the needle manually, use a needle threader.

- Secure Loose Threads:

- Ensure that loose threads and fabric edges are secured before sewing to prevent them from getting caught on the needle or other machine parts.

- Never Sew Over Pins:

- Remove pins from the fabric before they reach the needle. Sewing over pins can break the needle, damage your machine, or cause pins to fly out, potentially causing injury.

- Use a Properly Maintained Machine:

- Regularly maintain your sewing machine, including cleaning the needle area and ensuring that all components are in good working order. A well-maintained machine is less likely to cause accidents.

- Educate Children and Pets:

- If you have children or pets, teach them about the dangers of sewing needles and keep your sewing supplies out of their reach.

- Wear Appropriate Clothing:

- Avoid loose-fitting clothing or dangling jewelry while sewing, as these items can get caught in the machine or needle.

- Store Needles Safely:

- Store extra needles and sewing supplies in a secure location out of the reach of children and pets.

- Maintain Good Posture and Ergonomics:

- Sewing for extended periods can lead to discomfort or strain. Maintain good posture and set up your sewing area ergonomically to reduce the risk of muscle or joint issues.

By following these needle safety and best practices, you can minimize the risk of accidents and injuries while enjoying your sewing hobby or profession. Always prioritize safety and take the necessary precautions when working with sewing needles.