Man-made /Artificial fibers

Man-made fibers are fibers in which either the basic chemical units have been formed by chemical synthesis followed by fiber formation or the polymers from natural sources have been dissolved and regenerated after passage through a spinneret to form fibers. This fibre came to success when the researchers obtained a product by condensation of molecules presenting two reactive aminic groups with molecules characterised by two carboxylic reactive groups.

The fiber came to success when the researchers obtained a product (polymerized amide, from which the name polyamide) by condensation of molecules presenting two reactive aminic groups (hexamethylenediamine) with molecules characterized by two carboxylic reactive groups (adipic acid). In order to be differentiated from other polymers belonging to the same chemical class, this polymer was marked with the acronym 6.6 which indicates the number of carbon atoms (that is 6) in the two molecules forming the repetitive polymer unit.

Polyester fiber

This is the most important man-made fiber, with a production of 22 million tons in 2003 (58% continuous filament/42% staple fiber), which since some years overcame cotton production. The number of plants installed in the world is estimated already now at more than 500.

Another aspect of considerable importance under the geographic-economic point of view is the fact that 75% of the production is located in Asia. Polyester wrung the record of most produced synthetic fiber out from the polyamide fiber already in 1972 when it reached a share of 65% in the synthetic fiber market. Its success is due to its particular characteristics, to its versatility in the various application sectors and to the relatively low raw materials and production costs.

Polyamide fiber

This fiber category practically opened the textile market to fibers with no connection to the world of nature.

The production, performed worldwide by about 300 plants, amounts to 3,9 million tons (2003) and is distributed into polyamide type 6 (about 60%) and polyamide type 6.6 (about 40%); it is composed mainly of the continuous filament (85%), against 15% of staple fiber. The major producing countries are still Europe and USA (45% of the market).

Acrylic fiber

The production of this fiber is estimated at 2,6 million tons (2003) and West Europe is still today the area with the highest production (30%).

This fiber found its main use in the traditional wool sectors and is being produced in practice only in form of discontinuous or staple fiber.

It shows negligible production increases and consequently, its share in the man-made fiber market fell from 20% in 1970 to 9% in 2002.

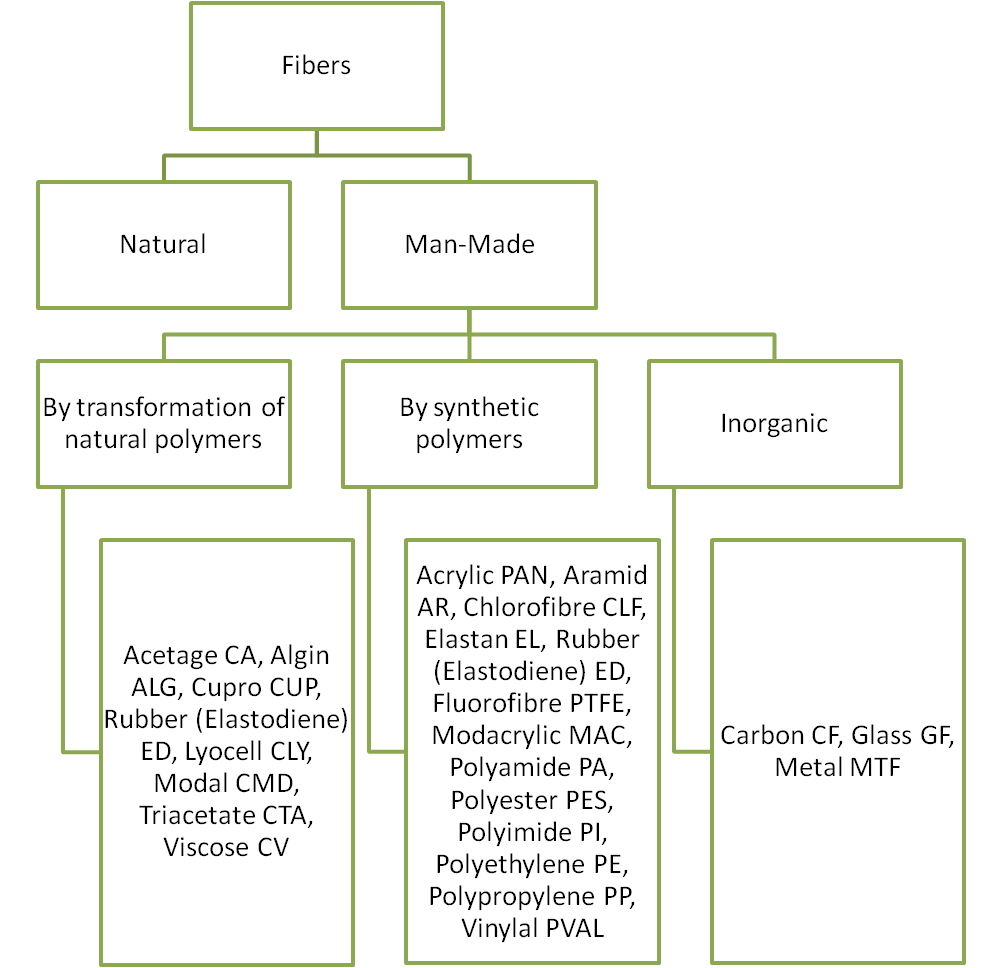

Types of textile fibers – list of textile fibers by its sources

A comprehensive textile fabric names by fiber sources

Types of Plackets in garment making

Type of plackets, parameters, and properties required for creating plackets

Polypropylene fiber

This is the last-born man-made fiber and, as it is used also in near sectors (as in the plastic industry), its importance in the textile sector was not always adequately monitored. In fact, even excluding such sectors, the production for merely textile uses (carpeting, clothing, technical uses) can be estimated at 3,0 million tons and shows steady growth rates. The most significant producer areas are Europe and USA.

Other man-made fibers

Within the group of fibers with high-tech performance, the elastane fiber (spandex) stands out for its characteristics of elongation and elasticity: its consumption in 2001 has been estimated at 160.000 tons.

Aramid fibers are appreciated for their mechanical and fireproof properties (consumption estimate in 2001: 33.000 tons), while carbon fibers are used in composite materials for hi-tech applications estimated consumption in 2001: 13.000 tons).

Elastane is produced mainly in Korea and in Taiwan (other producers: USA, Japan, Germany); aramid and carbon fibers are mostly produced in the USA and in Japan.

Manmade Fiber Classification

Characteristics and usage of Manmade Fibers

| Type | Characteristic | Major Uses |

|---|---|---|

| ACETATE |

|

|

| ACRYLIC |

|

|

| ARAMID |

|

|

| BICOMPONENT |

|

|

| LYOCELL |

|

|

| MELAMINE |

|

|

| MODACRYLIC |

|

|

| NYLON |

|

|

| OLEFIN |

|

|

| POLYESTER |

|

|

| PBI |

|

|

| RAYON |

|

|

| SPANDEX |

|

|