All About Industrial Stitching and Sewing Machine

Types of stitching or sewing machines, stitch machine components such as needles, feed systems, sewing machine motors, type of stitches, stitching defects, and safety measures

Industrial sewing machines are specialized machines that are designed to perform specialized tasks in high volumes. Various industrial sewing machines and their components and features are explained in this article.

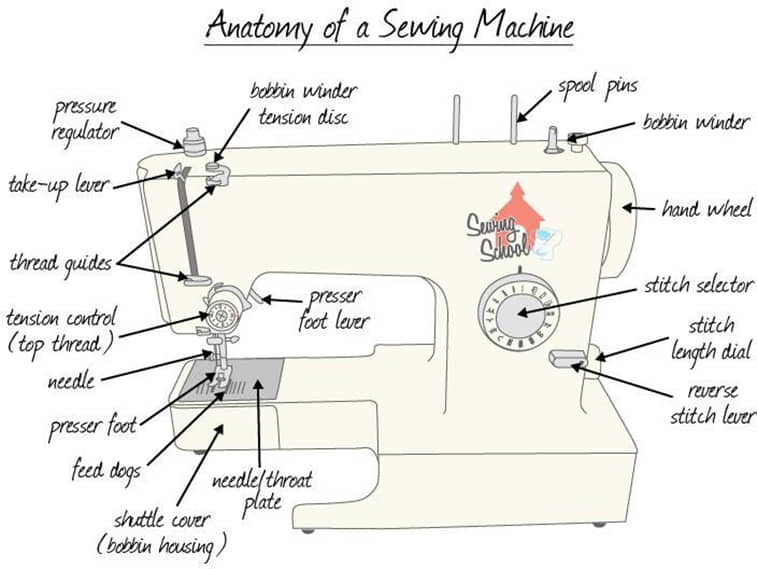

Parts of Sewing Machines

Handwheel

Spool pin

Spool Cap

Bobbin pin/winder

Thread guide

Take-up lever

Stitch selector

Presser’s foot

Presser foot pressure control

fabric

Presser foot lifter

Needle

Needle threader

Thread cutter

Needle clamp screw

Stitch plate

Feed dog

Throat

Bobbin cover

Foot control

Attachments In Sewing Machines (Work Aids)

Work aids are devices that are built into machines, added to them afterward, attached alongside, or made use of in whatever ways a resourceful engineer can devise to improve productivity, improve or maintain quality standards, reduce training time and minimize fatigue for the operator.

Work Aids can be divided into the following categories

Folder

Folders are used, as their name implies, in situations where fabric must be folded prior to sewing. They vary from the simple fold (which could be achieved by an operator alone, though only slowly and perhaps untidily) to extremely complex combinations of folders (which enable some to be achieved in a fraction of the number of stages that it would take without the folders) and indeed enable some to be achieved that would not otherwise be possible at all.

Folders are frequently used on machines having more than one needle

(Note – Choose the folders for the “product” which are being manufactured in the nearby Industry of the center.)

Binder

Many folders are available that add further items of self-fabric or other material to a garment and of these, many come into the category are known as Binder. Fabric Edges are frequently bound, either as a means of edge neatening or to create a decorative effect or both.

(Note -Use 28mm Piping folder for a practice session)

Hemmer

Folders that operate on a garment part without any additional material are known as Hemmer.

(Note -Use Shirt Bottom Hemming folder for a practice session)

Presser Foot

Presser feet can be used as specialized work aids, in addition to their normal function of holding the materials against the feed dog, when the scale of the situation is within the small size of the foot. The function of edge guiding can be performed in some circumstances by a special presser foot called compensating presser foot.

Guides etc.

Guides are used where sewing must take place in a certain position on a garment. In their simplest form, they are edge guides, forming some kind of physical barrier to the edges of the fabric being joined together

(Note: Use Variation of Straight and curved guide for a practice session)

Hi Komal, your article is very informative. We are selling small sewing machine with brand name akiara. I want some of your suggestion, can you contact me on agrawal _ amit _ s at hot mail dot com

You have said it all what I marveled about is the blind hem stitchine industrial machine in the Collage I went Vogue Style as twenty ten graduate

school of fashion and designing by Joyce Aba Bio was thought by hand Heming and Blind stitches was one mean the hand stitching thanks a lot guys.