All About Industrial Stitching and Sewing Machine

Types of stitching or sewing machines, stitch machine components such as needles, feed systems, sewing machine motors, type of stitches, stitching defects, and safety measures

Industrial sewing machines are specialized machines that are designed to perform specialized tasks in high volumes. Various industrial sewing machines and their components and features are explained in this article.

Different Types Of Sewing Machine Beds

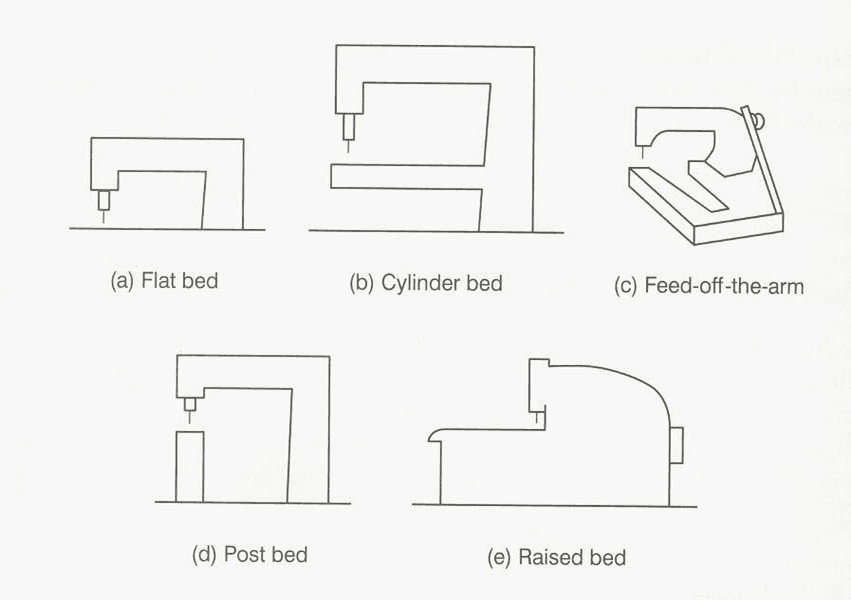

In fashion manufacture the machines are still predominantly used in their basic forms but, for more specialized garments and those made in higher volume, variations in machine shape are available which enables easier movement of the materials around the machine. These variations primarily affect the shape of the bed of the machine, i.e. the part on which material rest.

The best-known version is the flatbed and the main alternatives are cylinder bed, Post bed, and feed – off- the arm. The blind felling machine is also a special shape, as are the Overedge machines which have no fabric space to the right of the needle.

Following is the classification of different bed types used in machinery.

Flat Bed

The flatbed is used in the majority of sewing where a large and open garment part can easily be handled past the needle. It provides a suitable surface for all flat sewing and also facilitates the use of markers to control the position of the garment parts. For example, a patch pocket on a shirt front.

Cylindrical Bed

These beds are basically used where the parts to be sewn are small, curved, or otherwise awkward in shape.

Post Bed

It has the same applications as a cylindrical Bed.

Feed Of The Arm

The feed-off-the-arm machine is used where a lapped seam has to be closed in such a way that the garment part becomes a tube. They are common in jeans production where the outside leg seam is normally the type known as lap-felled and it is joined after the inside leg seam in the sequence of construction. The operator wraps the part to be sewn around the machine bed and it is fed away from the operator, off the end of the bed, as the operator sews.

Blind Stitch

This machine also consists of a different type of machine bed which is shown in the given picture. An example of the Blind machine’s use is in the bottom hem of trousers and sometimes on closing the curtains etc.

Overlock Machine Bed

Overedge machines also have a different type of machine bed (See picture) which has no fabric space to the right of the needle.

Type of sewing machine beds

| Types of Sewing Machine | Stitch Type | Features and Uses |

|---|---|---|

| Flatbed Machine (basis type) | Lockstitch, Chain stitch | The large working area allows a wide range of applications; the material can easily be guided around the needle and the presser foot. This basic type is used for all kinds of flat sewing work. |

| Raised bed machine | Lockstitch, Chain stitch | The bedplate is in the form of a plinth. It facilitates the assembly of pre-sewn parts and is especially suitable for the fitting of accessories and special attachments. This is the basic form for various specialized machines such as buttonholers. |

| Post bed machine | Lockstitch, Chain stitch | This type has an increased working height Special applications are found in the working of three-dimensional products. e.g. shoes and bags. The post bed makes it easier to work on tight curves and corners, sew in sleeves, and complete large, half-assembled products. |

| Cylinder bed machine | Lockstitch, Chain stitch | This type has an increased working height and a bed in the shape of a horizontal arm. It is especially suitable for working on tubular parts, such as cuffs, sleeves, and trouser legs, and also for button sewing and bar tacking. It is used extensively in the making of clothing from knitted fabrics. |

| Side bed machine | Chain stitch, Over-edge | Machines that are specialized for sewing at edges need only a small working area |

Different Types of Feed Mechanisms

Besides the basic motion of needles, loppers, and bobbins, the material being sewn must move, so that each cycle of needle motion involves a different part of the material. This motion is known as feed, and sewing machines have almost as many ways of feeding material as they do of forming stitches. For general categories, we have: drop feed, needle feed, walking foot, puller, and manual. Often, multiple types of feed are used on the same machine. Besides these general categories, there are also uncommon feed mechanisms used in specific applications like edge joining fur, making seams on caps, and blind stitching.

Functions of the Feed Dog

- Makes the sewing product move per

- Can change amount to move and forms stitches suitable for the sewing

- Stretch stitching or gathering stitching can be performed by means of a feed mechanism, and prevention of puckering, gathering, can be performed.

Different types of Feed

Bottom Feed

This is the most standard feed mechanism, which feeds material with a lower feed dog only. Uneven material feeding is likely to occur because of bottom feed only. However, sharp curve stitching can be easily performed and material handling is easy.

Needle Feed (Bottom Feed + Needle Feed)

This is the feed mechanism in which the needle bar moves in synchronization with the bottom feed. The feeding force is strong, and this type can feed material more precisely than the aforementioned bottom feed type sewing machine. Uneven material feeding is reduced, but, stitch shrinking due to thread tightness is likely to occur.

Differential Feed (Front Bottom Feed + Rear Bottom Feed)

This is the bottom feed mechanism, but the feed dog is divided into front and rear. This is the feed mechanism which is possible to intentionally stretch material or gather material by changing the feed amount of front feed dog and rear feed dog. This is suitable for sewing elastic knit.

Differential feed ratio (e.g. JUKI overlock sewing machine, MO Series) Gathering 1: 2 (Max. 1: 4)

Stretching 1: 0.7 (Max. 1: 0.6)

Bottom and Variable Top Feed (Bottom Feed + Top Differential Feed)

There is a feed dog on the top side in terms of the bottom feed, and the top feed amount can be adjusted simultaneously together with the adjustment of material feed from the bottom side. Accordingly, this is the feed mechanism that is possible to prevent sewing slippage and to perform edging contracting or gathering.

Differential Bottom Feed and Variable Top Feed

The bottom-feed is differential feed, and the top feed amount can be adjusted simultaneously together with adjustment (stretching and gathering) of material feed from the bottom side. Accordingly, this is the suitable mechanism that can give the most suitable feed amount to the upper and lower materials.

Unison Feed (Bottom Feed + Top Feed + Needle Feed)

The feed force of this mechanism is most superior and this feed mechanism is largely used for extra heavy-weight materials or the like.

Feed with Cloth Pulling Roller

The roller located in the rear of the presser foot pulls materials and sewing is performed. Uneven material feeding is reduced and working property is improved.

Fixed Feed

This is the feed mechanism to feed materials in a fixed state by holding materials between the lower plate and upper plate.

Hi Komal, your article is very informative. We are selling small sewing machine with brand name akiara. I want some of your suggestion, can you contact me on agrawal _ amit _ s at hot mail dot com

You have said it all what I marveled about is the blind hem stitchine industrial machine in the Collage I went Vogue Style as twenty ten graduate

school of fashion and designing by Joyce Aba Bio was thought by hand Heming and Blind stitches was one mean the hand stitching thanks a lot guys.