Denim Spinning Manufacturing Methods and Technologies

Denim fabrics are after all fabrics made with yarns of varying fibre properties and manufacturing processes. The article explains the process of spun yarn manufacturing in the context of denim fabrics manufacturing.

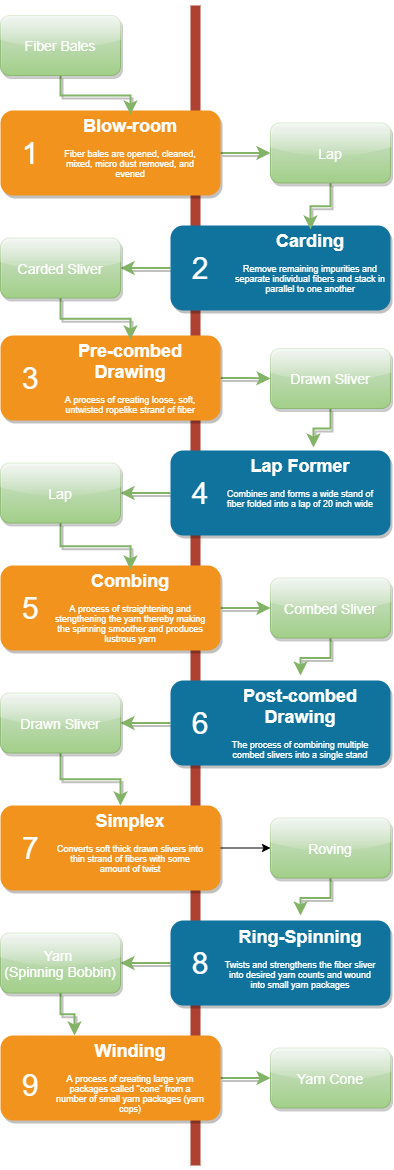

The warp yarn (length-wise) used in denim fabrics is uniquely prepared for denim manufacturing compared to conventional woven fabrics. The yarn goes through numerous processing steps before it is placed on the weaving machine. Unlike warp yarn, most filling yarn (width-wise) is put onto yarn packages and delivered directly to the weaving machine where it is inserted into the fabric without any further preparation in the same manner as conventional woven fabrics. The following flow chart reveals the necessary steps in the manufacture of denim fabrics, beginning with the production of the yarn.

Spinning for structured Denim yarns

Different spinning methods are available in making yarns, including ring-spun, rotor-spun, twistless, wrap-spun and core-spun yarns. The open-end spinning system spins yarn directly from slivers, using a spinning rotor and a withdrawal system that imparts a false twist to form the fibres into a yarn.

Ring-spun yarns

This is the most widely used method of staple-fibre yarn production. The fibres are twisted around each other to give strength to the yarn. Modern ring-spinning frames and open-end machines can be installed with devices that can manufacture predetermined yarn effects. These effects can vary from slubs (thick places) with different lengths, different spacing between slubs, or variations in the yarn count. Using these devices, OE yarns can have a more ring-spun like appearance, and ring-spun yarns can have an increased rough or “antiqued” quality.

Yarn spinners can design patterns and effects specific to their needs, which can be downloaded into the machine’s electronic control system. We need to know the spinning parameter Twist Multiplier and important yarn parameters, such as strength, count and their variabilities of various yarn types are Spinning Parameters and Yarn Quality. Rope dyeing technology demands fewer torque yarns in the warp which are made from “U” rotors. The “H” values of Yarns made from “U” rotors as tested in Uster evenness testers are higher by 2.0 to 2.5 numbers in comparison with the yarns produced from “T” rotors.

Cotton Mixing

Knowledge and understanding required for making mixing come from fibre test results, experience and management skills on bale management. A spinning mixing plan is prepared to execute on the mill floor. Lack of cotton fibre mixing knowledge leaves no way to explain, let alone avoid, defective yarn or fabric.

Method of quality cotton mixing evaluation, formulation and control of cotton mixing on yarn production costs

To operate manufacturing operations of spinning and weaving activities under cost controls and economic viability with high quality, productivity performance it is highly essential to design a computer model for the development of a mixing plan suitable for a particular fabric architectural construction. These need to feed fibre parameters data to like span length, fineness, uniformity ratio, bundle strength, elongation at break, maturity coefficient, Rd and +b values, trash content, type of trash, nep content etc., to forecast achievable yarn parameters like evenness, thick places, thin places, neps, hairiness, diameter, dust, trash, fineness of yarns, tensile strength and elongation, single yarn strength, CSP and twist which we need to have for our fabric weaving requirements. Moreover, we need to develop various machines setting charts through which the cotton fibres are to be processed to convert to yarns.

Technological values of cotton

The goal or objective of the present investigation is to determine the technological value of cotton, which should reflect the achievable level of yarn quality (yarn strength). In general, the cotton fibre criteria of this problem can be classified under three headings, namely tensile properties, length properties and fineness properties. Tensile properties can be divided into two sub-criteria, fibre bundle tenacity (FS) and elongation (FE). Similarly, UHML, UI and SFC are the relevant sub-criteria of length properties to be considered here. Fineness is solely represented by the micronaire (FF) value of cotton. At the lowest level of the hierarchy, there are more than 33 cotton fibre alternatives, which should be ranked according to their technological value.

Charts are to be prepared and to be displayed in the mixing room.

Natural Indigo Blue Dye Origin Dying Procedures Technology and Dye Recipes for Denim Fabrics

Natural INDIGO Dye – THE KING OF NATURAL DYES

Denim Fabric Weaving – Manufacturing Process, Methods, and technologies

Manufacturing process of Denim Fabrics

![]() Objectives of cotton mixing

Objectives of cotton mixing

Economy, processing performance and functional properties

In mixing different grades of the same fibres are kept together for yarn production. This is generally meant as the intermingling of different types of same fibres of the same or different grades of cotton bales. This involves the manipulation of a heterogeneous physical system with the intent to make it more homogeneous, cost-effective and has the ability to spinning process performance. This requires getting the required parameters for enabling spinning of yarn with specified technical parameters while ensuring the lowest economic cost and have consistency in yarn quality.

- Costs are reduced by mixing a cheap fibre with a more expansive fibre as per a defined mixing plan.

- This should combine properties of fibres in order to cover up fewer desirable characteristics in one fibre and give improved fabric performance.

- Improve wearing qualities

- Adequate conditioning of mixing before feeding to blow room

- Hold down raw material costs

- Influence favourably the material during processing

Spinners can see the results of excessive variability in fibre length or strength when manifested as yarn breaks and production halts. Knitters and weavers can see the knots and slubs or holes that reduce the value of fabrics made from defective yarns that were spun from the poor-quality fibre. Inspectors of dyed fabrics can see the unacceptable colour streaks and specks associated with variations in fibre maturity and the relative dye-uptake success. The grower, ginner, and buyer can see variations in colour or trash content of ginned and baled cotton.

Addition of 10% Recycled Waste

The full recycling of all opening and carding wastes, using a new line of machinery from Trutzschler and others, is attempted by few with a success. Its obvious importance in Denim manufacture lies in the overall weight on the final cost represented by the cost of cotton. Because of heavy yarns and fabrics, if one can save 3 or 4% on cotton costs, the impact on the bottom line can be remarkable.

This clean material has some residual trash in it not too different from the cotton used. Naturally, there are more short fibres. The yield will be approximately 50%, in other words from every 2 kgs of raw waste we get 1 kg of clean recycled cotton. This material is baled again and fed to the mix at the laydown. Normally 10% is used. A loss of some 0.5 to 1.0 cN/tex is then unavoidable, but with 10% it will be manageable.

Control of Yarn Realization

A one per cent reduction in yarn realization has almost the same economic impact on the mill’s profit as an increase of one per cent in the mixing cost. The control of yarn realization is thus as important to a mill as the control of cotton and mixing costs. One may find the detailed procedures for the control of yarn realization in Chapter 3, ATIRA Silver Jubilee Monograph “Process Control in Spinning”.

Mock Rings

Various attempts to duplicate superior denim made from ring yarns with rotor yarns of mock or slubby have always failed in fabric strength properties, fabric hand and appearance due to differences in yarn structure and yarn properties. Still one wonders how much of the present so-called ring-spun Denim is such and how many are mock ring made in the open end.

Other Value Offerings

Cotton rich polyester denim is with superior hand feel, lustre and colour contrast for the fashion market. One may find a deep value in using dyed polyester texturised filament yarn in place of costly yarn-dyed cotton weft for high fashion denim. Poly Spandex yarns are replacing core spun lycra yarns in the value universe. Within Poly Denims, the denier is getting coarser day by day from 300 to 450 to 600. Though Linen Vintage denim is not in high volume, there are efforts to replace it with Jute (Indian Linen) in the value proposition.

Successful strategies in denim mean profit, often (now) even survival. Engineering the fabrics on a continual basis provides a way to achieve both quality and cost benefits of substantial proportions. At the same time, full manufacturing flexibility through modularization is being maintained, enabling the denim mill to meet new and changing trends in raw material and fashion.

Objectives of cotton mixing

Objectives of cotton mixing