Fusing Conveyor Belt in Garment Making

The conveyor belts are the most delicate design elements of a continuous fusing machine. Their function, however, is crucial for the performance of all other elements. Therefore they have to meet with high expectations.

The conveyor belts are the most delicate design elements of a continuous fusing machine. Their function, however, is crucial for the performance of all other elements. Therefore they have to meet with high expectations.

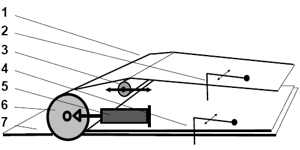

What is the Conveyor system?

| Name | Description |

|---|---|

| Cover Belt |

|

| Tracking Sensor |

|

| Control Roller |

|

| Safety Sensor |

|

| Belt Tensioning |

|

| Tensioning Roller |

|

| Transport Belt |

|

If primarily heavier fabrics are to be fused, or in case of sandwich or multi-layer fusing, higher heating capacity and a longer heating zone are needed to make sure that the machine capacity can follow the loading speed of the operators.

In this case heating form both top and bottom side with separate control is advisable to guarantee the correct temperature balance.

What’s a conveyor System?

The conveyor belts are the most delicate design elements of a continuous fusing machine. Their function, however, is crucial for the performance of all other elements. Therefore they have to meet with high expectations:

- They must be strong, with high tear and tensile strength.

- The surface must be smooth, to avoid marks or structure transfer on delicate fabrics.

- The surface should not allow any resin adherence.

- They must withstand temperatures up to 250 ° Celsius.

- They must be thin for optimum heat transfer.

- They may not change their dimensions when heated up.

- They must have a smooth Teflon coating.

- To avoid shifting of material they must have an antistatic treatment.

- To avoid marks they should not have a thick welding joint.

- The belt edges must be sealed, to avoid fraying.

It goes without saying that not only the belts but also the other design elements of the transport system of a fusing machine must offer the required precision and reliability:

- The speed of both belts must be perfectly synchronized.

- The tracking control system must be very sensible.

- Variations of the belt tension must be compensated automatically.

- The belt tension should be relatively high and precisely adjustable, in order to assure an even and intensive contact.