Terry towels – fabrics that can absorb large amounts of water

Design, manufacturing, and technological features of terry towels

A terry towel is a textile product which is made with pile loops on one or both sides covering the entire ground surface or forming pile strips, pile checks, or other pile patterns (with hemming end or with firm selvedges).

Construction of Terry Towels

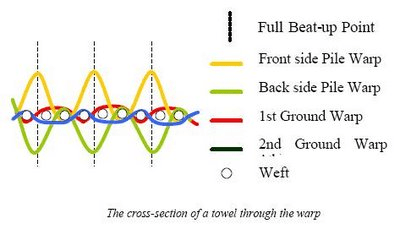

Terry towels are woven as 2, 3, 4, 5 or more pick terry weaves. The most common type is 3-pick terry towelling. The cross-section of a towelling through the Warps are divided into two systems as shown in Figure 3, pile warps and ground warps, whereas wefts consist of only one system. In basic Turkish Toweling, front side and back side pile warps and 1st and 2nd ground warp end form a 2/1 rib weave with each other.

The rib weaves which is formed by the pile warps is one pick ahead of the rib weave which is formed by ground warp ends. Warps are drafted throughout the fabric width 1:1 or 2:2 piles and ground warps. In 1:1 warp drafting order each ground warp end is followed by a pile warp end while in 2:2 warp drafting order each two ground warp ends are followed by two pile warp ends. In Figures 3a and 3b, the weave notation of 3 weft pile basic Turkish towelling is given in 1:1 and 2:2 warp orders.

As is seen from the weave diagrams in Figures a and b, the shedding of the ground warps is not synchronized with that of the pile warps. By this, the number of interlacing throughout the warp increases, and this strengthens the fabric. As it has been mentioned before terry towels can have pile loops on one or both faces. Different types of terry weave which have piled on one face and both faces.

Nano technology – Introduction, Definition, Market, Applications

Factors affecting electrospinning process

FP: Front Face Pile Warp

BP: Back Face Pile Warp

Little block: Ground warp is over the weft

Shaded: Front Face Pile Warp is raised over the weft

X: Back Face Pile Warp is raised over the weft

Empty space: Warp is lowered behind the weft

The picks used for towelling is between 15 and 25 picks/cm. And ends used are between 20 and 30 ends/cm. During the weaving of borders, the picks are increased 3 to 6 times the density in the pile areas Pile/ground ratio is described as the length of pile warp per unit length of fabric in the warp direction.

A practical way to find out this ratio is done by measuring a 10 cm length of towelling in the warp direction, then cut the pile warp from either end of the measured length and measure the total length of the removed pile end per 10 cm length of fabric. Pile warp length per 10 cm fabric is usually between 20-100 cm. This ratio has a direct effect on the fabric weight and thickness. As the ratio increases, the weight and the thickness of the terry fabric increases.