Non-Woven Fabrics

Non-woven, origin, properties, and application

Nonwovens do not depend on the interlacing of yarn for internal cohesion. Intrinsically they have neither an organized geometrical structure. They are essentially the result of the relationship between one single fiber and another. This provides nonwoven fabrics with characteristics of their own, with new or better properties (absorption, filtration) and therefore opens them up to other applications.

Manufacturing Process of Non-Wovens

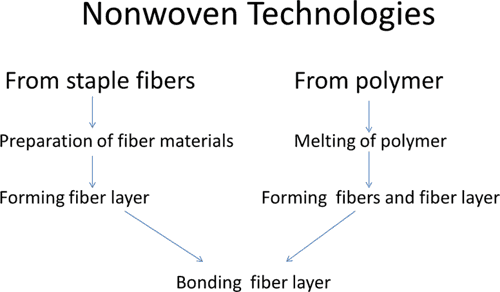

Nonwoven emerged from the textile, paper and plastic industries and has, for over 40 years, evolved into a distinct industry. As the demand for nonwovens has steadily increased, it has been met by the technology and ingenuity of raw materials and equipment suppliers, and nonwoven producers and converters. The production of nonwovens can be described as taking place in three stages, although modern technology allows overlapping of some stages, and in some cases, all three stages can take place at the same time.

Stages of Non-woven Processing

- Web Formation

- Dry laid

- Carded

- Air laid

- Spun melt

- Spun laid (or spun-bonded)

- Melt blown

- Wet laid

- Other technologies

- Electrostatic spinning

- Flash spun

- Dry laid

- Web Bonding

- Chemical

- Thermal

- Mechanical

- Needle punching

- Hydro-entanglement

- Stitch bonding

- Finishing Treatments

The opportunity to combine different raw materials and different techniques accounts for the diversity of the industry and its products. This diversity is enhanced by the ability to engineer nonwovens to have specific properties and to perform specific tasks.

Manufacturing processes

Nonwovens are typically manufactured by putting small fibers together in the form of a sheet or web (similar to paper on a paper machine), and then binding them either mechanically (as in the case of felt, by interlocking them with serrated needles such that the inter-fiber friction results in a stronger fabric), with an adhesive, or thermally (by applying binder (in the form of powder, paste, or polymer melt) and melting the binder onto the web by increasing temperature).

Staple nonwovens

Staple nonwovens are made in 2 steps. Fibers are first spun, cut to a few centimeters in length, and put into bales. These bales are then dispersed on a conveyor belt, and the fibers are spread in a uniform web by a wet-laid process or by carding. Wet laid operations typically use 1/4″ to 3/4″ long fibers, but sometimes longer if the fiber is stiff or thick. Carding operations typically use ~1.5″ long fibers. Rayon used to be a common fiber in nonwovens, now greatly replaced by PET and PP.

Fiberglass is wet-laid into mats for use in roofing and shingles. Synthetic fiber blends are wet-laid along with cellulose for single-use fabrics. Staple nonwovens are bonded by using either resin or thermally. Bonding can be throughout the web by resin saturation or overall thermal bonding or in a distinct pattern via resin printing or thermal spot bonding. Conforming with staple fibers usually refers to a combination with melt-blown, often used in high-end textile insulations.

Melt Blown nonwovens are produced by extruding melted polymer fibers through a spinnet or die consisting of up to 40 holes per inch to form long thin fibers which are stretched and cooled by passing hot air over the fibers as they fall from the die. The resultant web is collected into rolls and subsequently converted to finished products.

The extremely fine fibers typically polypropylene differ from other extrusions particularly spun-bond in that they have low intrinsic strength but much smaller size offering key properties. Often melt blown is added to spun bond to form SM or SMS webs, which are strong and offer the intrinsic benefits of fine fibers such as fine filtration, low-pressure drop as used in face masks or filters, and physical benefits such as acoustic insulation as used in dishwashers. One of the largest users of SM and SMS materials is the disposable diaper and feminine care industry.

Spunlaid nonwovens

Spunlaid nonwovens are made in one continuous process. Fibers are spun and then directly dispersed into a web by deflectors or can be directed with air streams. This technique leads to faster belt speeds and cheaper costs. Several variants of this concept are available, but the Leading technology is the REICOFIL machinery. PP spun bonds run faster and at lower temperatures than PET spun bonds, mostly due to the difference in melting points.

Spun bond has been combined with melt-blown nonwovens, conforming them into a layered product called SMS (spun-melt-spun). Melt-blown nonwovens have extremely fine fiber diameters but are not strong fabrics. SMS fabrics, made completely from PP are water-repellent and fine enough to serve as disposable fabrics. Melt blown is often used as filter media, being able to capture very fine particles. Spun laid is bonded by either resin or thermally. Regarding the bonding of Spun laid, Rieter has launched a new generation of nonwovens called Spun jet. In fact, Spun jet is the bonding of the Spun laid filaments thanks to the hydroentanglement

Air-laid paper

Air-laid paper is a textile-like material categorized as a nonwoven fabric made from wood pulp. Unlike the normal papermaking process, the air-laid paper does not use water as the carrying medium for the fiber. Fibers are carried and formed to the structure of paper by air.

Other Nonwovens

Nonwovens can also start with films and fibrillate, serrate or vacuum-form them with patterned holes. Fiberglass nonwovens are of two basic types. Wet laid mat or “glass tissue” use wet-chopped, heavy denier fibers in the 6 to 20-micrometer diameter range. Flame attenuated mats or “batts” use discontinuous fine denier fibers in the 0.1 to 6 range. The latter is similar, though run at much higher temperatures, to melt-blown thermoplastic nonwovens. A wet-laid mat is almost always wet resin bonded with a curtain coater, while batts are usually spray bonded with wet or dry resin. An unusual process produces polyethylene fibrils in a Freon-like fluid, forming them into a paper-like product and then calendaring them to create Tyvek.

Bonding Process

Both staple and Spun laid nonwovens would have no mechanical resistance in and of themselves, without the bonding step. Several methods can be used:

- thermal bonding

- Use of a heat sealer

- using a large oven for curing

- calendaring through heated rollers (called spun-bond when combined with Spun laid webs), calendars can be smooth-faced for an overall bond or patterned for a softer, more tear-resistant bond

- hydro-entanglement: the mechanical intertwining of fibers by water jets (called spun lace)

- ultrasonic pattern bonding: used in high-loft or fabric insulation/quilts/bedding

- Needle punching/needle felting: the mechanical intertwining of fibers by needles

- Chemical bonding (wet-laid process): use of binders (such as latex emulsion or solution polymers) to chemically join the fibers. A more expensive route uses binder fibers or powders that soften and melt to hold other non-melting fibers together

- one type of cotton staple nonwoven is treated with sodium hydroxide to shrink bond the mat, the caustic causes the cellulose-based fibers to curl and shrink around one another as the bonding technique

- one unusual polyamide(Cerex) is self-bonded with gas-phase acid

- Melt blown: fiber is bonded as air attenuated fibers intertangle with themselves during simultaneous fiber and web formation.

Needle punched Nonwovens Process

- Start with staple fiber bale stock

- Fibers are carded and cross laid to the desired weight

- Fiber batt is mechanically needled by oscillating needle board

- Barbed needles entangle the fibers vertically

- The more needle boards, the denser the fabric

Spunlaced Nonwovens Process

- Start with staple fiber bale stock

- Fibers are carded to form a batt

- The batt is either laid on a mesh conveyor or over perforated cylinders

- The batt is then subjected to very high-pressure water

- Water entangles the fibers, creating a stable fabric

Fig: Spun laced Nonwovens Process

Cross layering- Vertical cross-lapper or Camel-back

- Carded web

- Feeding belts

- Couple of reciprocating belts

- Output belt

Mechanical methods

Carding- In the carding process, individual staple fibers are separated from clumps of fibers and more or less uni-directionally oriented.

Nonwovens roller card

Cross layering-horizontal cross-lapper

- Web

- Feed belt

- Upper conveyor belt

- Lower conveyor belt

Perpendicular laying

- Carded web

- Reciprocating comb

- Conveyor belt

- Wire grid

- Compressing bar

Aerodynamic forming device

- Condensor screen

- Lickering

- Fan

- Duct

Combined mechanical-aerodynamic methods

- The random card

- Random roller

- Condensing roller

- Two doffer

Wet forming device

- Dispersion inlet

- Inclined wire screen

- Dewatering pipes

- Suction box

- Formed sheet

After Treatment

The production line is 2.2 meters wide, capable of treatments of flame retardant, hydrophobic, oil & water repellent, powder coating, etc.

We are engaged in this area for more than ten years, different kinds of nonwoven fabrics such as coating laminated or composited nonwoven fabrics

we are manufacture of all type of nonwoven fabric in india

any reuirement to contact me +91 8200595433

Dear sir,

I have one new idea for making of non woven fabric.

Dear Sir.

This is Eng.Taqwa Alzubi, from JERASH THE FIRST Company.

We are an American company that produces PPEs (Personal protective equipment) located in Amman.

We are looking for a fabric supplier, SMS, PP PE Laminated.

Our target GSM =20,25,30,35,40 , both blue & white colors.

Can you provide us with SMS, PP, or PE fabrics, GSM=20,25,30,35,40?

Wating for your promoting reply.

Regards.

Eng.Taqwa Alzubi

As a nonwoven fabric factory:

Www.cswf.cn,we are proud of what we are working.As a Chinese non woven fabric factory,we are proud of what we are working

Non Woven Fabrics is best for environment health parknonwoven.com also manufacturers and suppliers of the non woven products.

We focus on

www.jcppfabric.comnon woven geotextile,Our Non Woven Geotextiles are comprised of strong polypropylene or Polyester staple fibers.