Cotton Fibers and its Properties

Properties, classification, and methods to identify the attributes of cotton fibers

USTER® HVI is used for measurement of the most important cotton fiber properties of micronaire, fiber length (UHML), uniformity, short fiber index, strength, elongation, color, trash content, and degree of maturity.

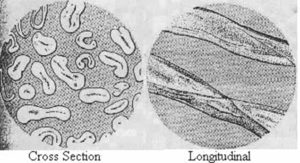

Microscopic Appearance of Cotton Fiber

Different kinds of fibers can be identified by their microscopic appearance better, than their physical appearance. When cotton is viewed under a microscopic lens; In longitudinal view, it appears as a flat tube with spiral twists or a twisted ribbon. Under the cross-section view, it is bean-shaped.

Properties & Uses of Cotton Fiber

The fibers are sent to a textile mill where carding machines turn the fibers into cotton yarn. The yarns are woven into cloth that is comfortable and easy to wash but does wrinkle easily. Cotton fabric will shrink about 3% when washed unless pre-treated to resist shrinking.

Cotton is prized for its comfort, easy-care, and affordability and is ideal for clothing, bedding, towels, and furnishings.

Properties of Cotton by Physical Structure

Color

The color of cotton fiber is instrumental in fiber identification. The usual color of cotton fiber ranges from white to creamy white. The color of fiber depends upon the conditions under which cotton is produced e.g., time of picking, the soil of growth, exposure of the plant to sunlight, climatic conditions, impact of insects and fungi, etc. The cotton produced normally has a cream-white color. If fiber is not picked at the right time, its color may vary. If fiber is left for an extended period of time in the boll, it may turn bluish-white. There are five recognized groups of color: white, gray, spotted, tinged, and yellow stained. As the color of cotton deteriorates the processability of the fibers decreases.

Fiber Strength

Fiber strength is measured in grams per denier (gm/den). Cotton is a moderately strong fiber. It has a tenacity of 3.0 – 4.9 gm/den. The strength of the cotton fiber is directly affected with the moisture regain and higher length. Wet cotton fiber is 20% stronger than dry cotton fiber. Similarly, long cotton fibers are stronger than short fibers.

Elastic Property

The elasticity of cotton fiber is very low. Recovery from the deformation of cotton fiber from the applied load is very low as cotton fiber is a rigid fiber and inelastic. At 2% extension, it has an elastic recovery (ER) of 74%. At 5% extension, it has an elastic recovery (ER) of 45%. Elastic property can be achieved by; Chemical treatments for the purpose of improvement increase recovery but fibers become harsher due to chemical treatment. Blending or mixing of cotton with elastic fiber, e.g. polyester.

Length

Physically the individual cotton fibers consist of a single long tubular cell. Its length is about 1200-1500 times its breadth. The length of cotton fiber varies from 16mm to 52 mm or ½ to 2½ inches depending upon the type of cotton. The width varies between 12 to 20 microns, e.g.Indian cotton- 16-25 mm American cotton- 20-30 mm Sea Island- 38-52 mm Egyptian cotton- 30-38 mm

Fineness

The fineness of the fiber depends upon the length of the fiber. As cotton fibers are longer in length, they have high fineness. Fineness is expressed in terms of decitex and it varies from 1.1 – 2.3 decitex in cotton fibers. Shorter cotton fibers have low fineness.

Length Uniformity

Length uniformity or uniformity ratio is determined as “a ratio between the mean length and the upper half mean length of the fibers and is expressed as a percentage”. A low uniformity index shows that there might be a high content of short fibers, which lowers the quality of the future textile product. Hence, fibers with high length uniformity produce good quality products.

The typical length uniformity of cotton fibers is shown as below;

| Length Uniformity | Uniformity Index [%] |

| Very High | >85 |

| High | 83-85 |

| Intermediate | 80-82 |

| Low | 77-79 |

| Very Low | <77 |

Crimp

Cotton fiber is more or less twisted on its longitudinal axis which can’t be seen from outside. This is called fiber crimp. The twist in the fiber doesn’t tend to be continuous in one direction i.e. if the first director of the fiber is right, and then the direction of the fiber is left. This property of cotton fiber helps in spinning.

Specific gravity

The specific gravity of cotton fiber is 1.54.

Effect of Sun-light

When cotton is exposed to sunlight, there is a gradual but consistent loss of strength of cotton fibers and they turned yellowish due to sunlight. When heat is promoted and brought to cotton fibers by sunlight, degradation of cotton is done by oxidation. From sunlight, much of the damage is caused by ultraviolet light.

Effect of Heat

Cotton is very resistant to degradation by heat. It begins to turn yellow after being burnt at 120° C for several hours. Decomposition of cotton fiber occurs at 150° C due to the process of oxidation. Cotton is severely damaged after a few minutes after at 240° C. Cotton burns readily in the air.

Luster

Cotton fiber has a very low luster naturally just like low elasticity.

Effect of Moisture

The tensile strength of the cotton fiber is increased with the absorption of moisture. Under normal humidity conditions, cotton takes up about 6 – 8% moisture. Cotton fiber has a moisture regain of 8.5%. Wet cotton fiber is 20–25 % stronger than dry cotton fiber as hydrogen bonding is produced between molecules of water and cellulose present in cotton. Hydrogen bonding becomes the cause of strength in wet cotton fiber.

Effect of Age

A small loss of strength is shown by cotton when stored carefully. After 50 years of storage, cotton may differ only a little from new fibers.

Smell

Cotton fiber burns rapidly in the air. Cotton burns instantaneously when it comes in contact with flame. Cotton burns quickly and readily with the smell of burning paper.

Conductor

Cotton is a very good conductor of heat and air. Cotton is a good conductor of electricity.

Properties of Cotton by Usage

Comfort

Cotton fiber has a large amorphous portion and this is why the air can be in and out through cotton fiber. So, the fabric made of cotton fiber is quite comfortable to use.

Soft Handle

Cotton fiber, if properly ginned, gives the best soft handle feeling among all other fibers. This property is instrumental in fiber identification.

Absorbent

Cotton fiber has high absorbency power and this is why this fiber can be died properly and without any problem or difficulty. It absorbs perspiration quickly which is its highly esteemed property. As the body perspires, cotton fibers absorb the moisture and release it on the surface of the fabric, so it evaporates.

Printing

The printing efficiency of cotton fiber is good. If the printing is applied on cotton fiber, it seems it doesn’t spread the color outside the design.

Good Color Retention

Cotton fibers have very good color retention. Fabrics made by it can retain their color in harsh conditions and in washing.

Machine Washable & Dry Cleanable

Cotton fiber has very good fatness and is easily washable. It is seen that some fibers can’t be dried or washed due to their sensitivity to water and weak fastness properties. You can easily wash the cotton-made fabric by machines and even you will be able to dry this fiber by using an electronic drier. Cotton fabric is very easy to launder.

Good Strength

Cotton fiber is a moderately strong fiber. Its strength along with its other properties makes it ideal for wear. Cotton fiber is also very durable.

Draping:

The drape-ability of cotton fiber is quite good. You can use the cotton fiber-made fabric in any kind of wear that needs more flexibility and drapes.

Sewing & Handling Is Easy:

The sewing efficiency on Cotton made fabric is easier and more comfortable than other fibers. Cotton is very easy in handling.

Breathability:

Fabric made from cotton fiber has very high air permeability which makes it highly breathable fabric. It has a distinctive feature that it adjusts easily with climatic requirements. That is why it is called all-Season fabric. In the summer season, the cotton fabric keeps the body cool and absorbs sweat easily. As the body perspires, cotton fibers absorb the moisture and release it on the surface of the fabric, so it evaporates.

Chemical Properties of Cotton

Effect of Acids

Cotton is damaged by dilute acids and cold concentrated acids which causes disintegration.

Effect of Alkalis

Cotton has excellent resistance to alkalis. It swells in caustic alkalis like NaOH but it doesn’t damage by alkali. It can be washed repeatedly in soap solution without any problem.

Effect of Organic Solvent:

Cotton has a high resistance to normal cleaning solvents. Cotton is dissolved by copper complexes such as cuprammonium hydroxide etc.

Effect of Insects

Cotton is not attacked or damaged by moths or beetles.

Effect of Micro-Organism:

Cotton is attacked by fungi and bacteria. Mildews feed on cotton fiber, rotting and weakening the material. Mildews and bacteria will flourish on cotton under hot and humid conditions.

Use of Cotton Fiber

- Cotton fiber can be woven or knitted into fabrics such as velvet, corduroy, chambray, velour, jersey, and flannel.

- It is used to make breathable textile products like underwear, socks, and T-shirts.

- Cotton is also used in fishnets, coffee filters, bookbinding, and archival paper.

- Linters are the very short fibers that remain on the cottonseed after ginning. They are used to produce goods such as bandages, swabs, banknotes, cotton buds, and x-rays.

- Bed sheets are usually made of cotton because of their soft feel.

- Cotton fiber is also used to create tents and cotton paper. Cotton paper is used to create banknotes and high-quality art paper.

- Cotton is used in apparel; blouses, skirts, pants, shirts, children’s wear, activewear, etc.

- Cotton is used in home upholstery; draperies, curtains, bed sheets, towels, table cloths, table mats, napkins.

- Cotton is used to make medical textile-like bandages and wound plasters.

- In short, cotton fiber is a versatile fiber that has a wide variety of uses.

| Property | Evaluation |

| Shape | Fairly uniform in width,

12–20 micrometers; Length varies from 1 cm to 6 cm (½ to 2½ inches); The typical length is 2.2 cm to 3.3 cm (⅞ to1¼ inches). |

| Elasticity | Relatively Low |

| Specific Gravity | 1.54 |

| Tenacity (strength) | |

| Dry Wet | 3.0–5.0 g/d3.3–6.0 g/d |

| Resiliency | Low |

| Density | 1.54–1.56 g/cm³ |

| Moisture Absorption | |

| Raw Conditioned | 8.5% |

| Saturated | 15–25% |

| Mercerized | 8.5% |

| Conditioned | 10.3% |

| Saturated | 15–27%+ |

| Dimensional stability | Good |

| Resistant To | |

| Acids | Damage, weaken fibers |

| Alkali | Resistant; no harmful effects |

| Organic Solvents | High resistance to most |

| Sunlight | Prolonged exposure weakens fibers |

| Microorganisms | Mildew & rot-producing bacteria damage fibers |

| Insects | Silverfish damage fibers. |

| Thermal Reactions | |

| To Heat | Decomposes after prolonged exposure to temperatures of 150˚C or over. |

| To Flame | Burns readily. |

Process of making Cotton fabric?

- Cotton is picked up from the fields. The seeds are separated by combing. This process is known as ginning.

- Ginned cotton is compressed to form bales. These bales are sent to the spinning mills.

- The cotton bales are loosened and cleaned. This process is known as carding.

- The cotton fibres are then converted into rope-like loose strands. The strands are twisted to make yarns. This process is known as the spinning of cotton yarns.

- The yarns are then used to make fabrics by weaving and knitting.

Everyone works daylight and night to achieve their desired goals. But after play a role well ahead conduct yourself, they compulsion strong nap by lying around a soft sheet. Hence, the cotton flat sheet is soft to the be against and courteous to use. Once you begin using these textile buying house wont opt for supplementary bedsheets in town. There are many fascinating aspects that a wise person along with you should know.

nice details.

Draw sheetsYou are not giving clear properties!

Write properties in easy way

I need more properties in easy words

I needed more properties.

hi 🙂